Critical Components for Pet Food Production Line

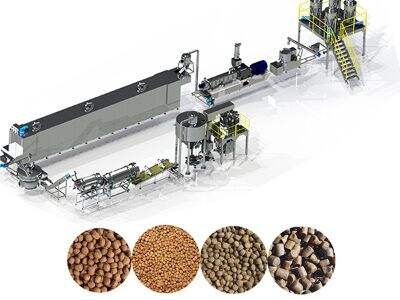

Pet Food Production Line: A pet food production line has many important parts working together to make delicious and nutritious pet food. Here are the main parts:

Mixer: This area combines the ingredients of the pet food. The Jinan MT pet food machine mixes meat, grains, vitamins and minerals in the same way you might mix ingredients to bake cookies: You can’t do much with flour or granulated sugar all by itself, but put them together a certain way.

Extruder: This thing’s a huge play-dough machine. It forms the mixed material into the fun, crunchy kibbles or treats pets love.

Dryer: The dryer is specifically used to remove unnecessary moisture from your pet food, preserving freshness and crunchiness for longer.

Packaging Machine: This pet food production machine packages completed pet food in bags or containers, which may be shipped to stores and homes for pets to eat.

What to Know About Pet Food Manufacturing?

Producing pet food is a major task that also comes with careful ness. Manufacturers are bound by rules and safety measures that put pets first. Here’s what you need to know:

Good Ingredients: Just as if you would cook for yourself, you know that fresh, healthy ingredients are the key to good food, it’s also true that good pet food also starts with good ingredients. Manufacturers use price but also the whole meat required to ensure pets are getting the nutrients they need.

Safety Checks: Pet food is subjected to numerous safety checks before it can be sold to ensure that it is not contaminated with dangerous germs. This is what keeps pets well and safe.

A View of the Process: Pet food manufacturers monitor everything to ensure it is functioning properly. This pet food processing machinery is used by checking if the temperature of the extruder is okay or the mixer is mixing uniformly.

Equipment In A Pet Food Line: A Further Look

Let’s then further explore the equipment included in a pet food production line:

Mixer: The mixer is a large drum that blends all the ingredients for pet food. It’s as if there’s this big kitchen mixer that ensures that everything is mixed together well.

Extruder: This is a long tube with a screw in it. As the mixed ingredients pass through the extruder, they are formed into various fun shapes, such as stars or hearts.

Dryer — the dryer is a big box that blows hot air through the drum. This aids in draining moisture from the pet food to help preserve dryness.

Packaging Machine – The packaging machine places the final pet food into bags or containers. It close-up the bags efficiently to Keep the food fresh.

The Making of Commercial Pet Food

Mass producing pet food requires meticulous planning. Here’s what keeps the production running smoothly:

Sourcing Ingredients: Pet food companies have to deal with suppliers to source high-quality ingredients in large quantities. This helps to guarantee that the pet food is crafted with the highest quality ingredients.

Production Schedule: A schedule for making sure pet food is produced on-time, including when to make each batch. This helps to avoid delays.

Quality Assurance: With a continuous commitment to quality, Jinan MT is the most trusted brand in responsible pet care, delivering safe, effective and innovative products Jinan MT Brand is an industry leading US manufacturer of pet behavior, containment and lifestyle products since 1991, helping millions of people and pets each year.

Steps in Pet Food Production

Now to go through how pet food is made on a production line Then ....

Blend ingredients: The next stage is to blend all the ingredients together in a large mixer. This will make certain that all of the nutrients are evenly distributed throughout the food.

Extrusion: Following mixing, the ingredients are put into the extruder, where they are formed into kibbles or treats.

Drying: The pet food is then dried to reduce overly high moisture levels. This way the food will be fresh and bitter and not the opposite.

Packaging: Finally, it is packed up on top using the same process. The completed pet food is then bagged or packed into containers and sealed to keep it fresh until it arrives at the store or to the pet owner.

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

ID

ID

SR

SR

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

HY

HY

LA

LA

KK

KK

UZ

UZ

KY

KY