Hello there. We are not going to speak about something quite, we going to talk a cool one: Twin screw extruder food processing. This incredible technology has to do with using being trackers, real-deal machines behind the scenes making food faster and tastier. So matter of fact it helps food companies produce all kinds tasty treats that we love to eat.

Have you ever wondered how fast food companies can produce so much in such a limited amount of time? It seems like magic, right? No. It is high-speed food processing technology, also the Jinan MT's product such as cereal extruder. That means, these machines are super fast and can mix, chop as well cook different ingredients too within seconds. It allows them to make wonderful food products that we can enjoy each day.

So, what happens here is the work of an extruder? A high torque, heavy-duty machine that has two large screws (the same kind of giant screws you might find in a toolbox, as well as the indomie making machine innovated by Jinan MT. It has some screws here that turn fast and push the food around in there. They morph and twist into different forms of themselves as they pass through. It is a magic show. — of sorts with food.

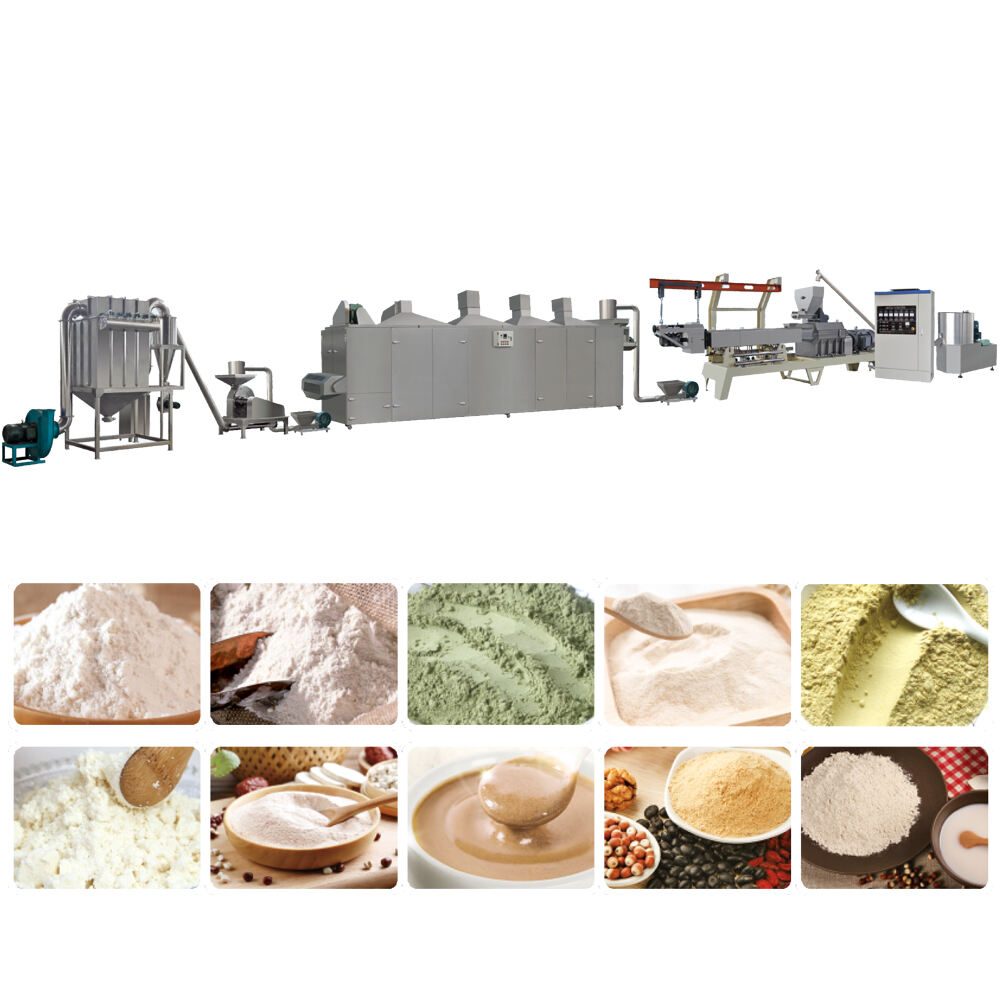

For instance, a twin screw extruder can process the hard cereals like corn and rice into soft puffy snacks such as popcorn and pop rest. It is some sort of the simple turns into fascinating. Even vegetables and fruits can be converted into powders that you sprinkle to flavor so many other foods. That means it can even be used for things like veggie sausages, and burgers in the event you need a break from real meat. That openness includes a wider range of choices for all eaters, meat-reducers included.

A twin screw extruder assists businesses in their likely so many ways, along with Jinan MT's product corn puff extruder. These make them to cook food faster and even, that will allow their production rate of at least 10 times more than a small fast casual restaurant selling same price. This is a good thing because it allows businesses to be competitive with each and ultimately reach more customers. Entrepreneurs creating delicious food at a reasonable cost is a win-win for all parties involved.

Twin screw extruders also make it possible for companies to generate new food items through their processes, which may be healthier and more sustainable for consumption, as well as the corn extruder machine from Jinan MT. An example is, create plant-based meats for businesses that are healthy and better alternative meat solution such as greenhouse gases. It is possible for us to eat deliciously without harming the world and our future.

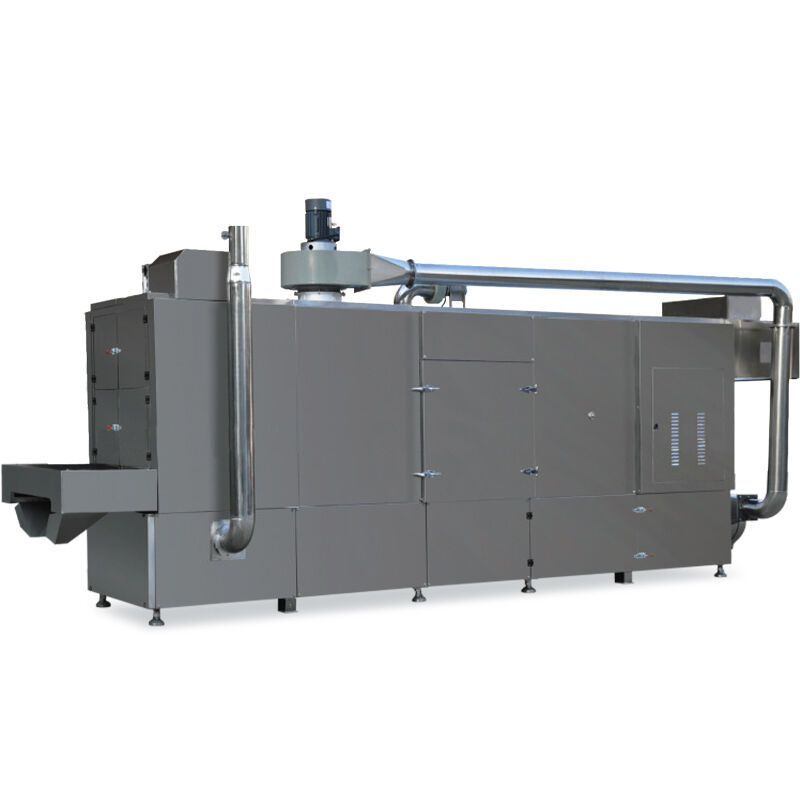

Variety of ingredients are mixed together carefully and then its fed to the extruder, just like the Jinan MT's product called dry dog food making machine. So this is almost like cooking a unique recipe. Then the screws spin quickly and force the ingredients through. From all over to a kaleidoscope of moving colors and shapes whipped around, as they go through the oven and come out cooked. It is interesting to see what the ingredients transform in.

Strong supply chain and production capacity as well as a variety of Twin screw extruder food processing. Flexible and able to provide custom-designed services. Standards that are rigorous and independent and auditing procedures.

Our equipment has built a strong recognition in the marketplace. We provide a turnkey service, from raw material preparation to Twin screw extruder food processing, with MCC Control System. The entire process line is an extremely high degree of productivity and automation. The customization is based on the needs of the customer.

With over 20 years of experience in the working as an engineering team, we hold many special patents on Twin screw extruder food processing and projects like multi-choice, low energy consumption drying system, high accuracy food extrusion system the corn flatten machine, unique, complete automatic packing and stacking system etc.We offer formulas for production installation, debugging, and instruction for the operator until you are happy products can be manufactured.Comparing to our competitors our product is high efficiency, energy-saving superior quality affordable price, and complete service before and after sales.

Twin screw extruder food processing offers excellent after-sales assistance customers worldwide includes fast responses clear smooth communication technical support ensure any issue can quickly addressed experienced team is hand assist any issues questions providing quick efficient solutions approach support led an increase customer satisfaction strengthened status reliable partner international trade focusing needs customers maintaining open lines communication MT machinery ensures clients receive best level support care commitment providing exceptional after-sales services not improves customer purchasing experience also fosters long-term friendly cooperation relationships them