Have you ever wondered how your beloved snack is produced? Another machine which is required for preparation of snacks are the corn puff extruder machines. This thing is so neat because it makes very thin puffs of corn in no time at all for companies that make tasty corn kibbles. These are simply light and crunchy snacks made with corn that come in a variety of fun shapes. Here we will see everything about the working of this awesome machine and what makes it extra special.

The corn puff extruder machine is a special device for preparing crunchy snacks from the endosperm part of maize, identical to Jinan MT's product pet food production plant. It involves cornmeal (a meal made from ground up kernels of maise) being mixed with water and other stuff. The machine then forces this mixture through dies of specific shapes. Basically like molds that the corn puffs are driven through to create many fun features and making them look attractive for children as well grown-ups. The different shapes will more fun eat the snacks.

Extruder: This is the core part of corn puff extruder machine, also the breakfast cereal making machine made by Jinan MT. where the magic goes on. Extruder: A long tube with a screw inside of it. Cornmeal goes into the extruder, and starts going through (Hilander) And when it comes out the other end, a perfectly shaped corn puff. The motion of this one machine makes so many delectable snacks.

The cornmeal is piped from the extruder onto screens, heated with steam and then injected with water to give it a doughy sensation. As the dough travels through the tube, a screw inside of it helps to make hot and squishy. This is what gives the dough its shape that resembles a corn puff and transforms it from raw ingredients into an enjoyable snack.

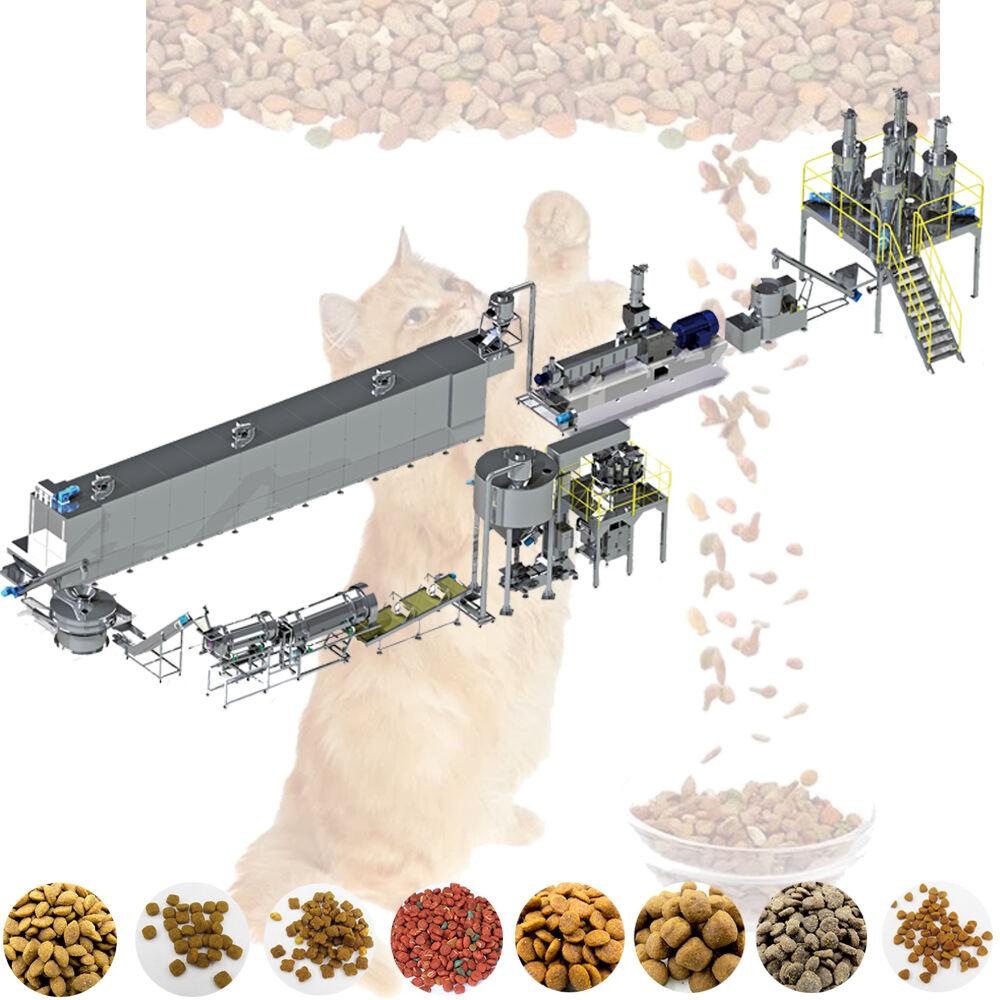

The machine processes corn kernels, which are the little seeds of the corn plant, along with Jinan MT's product pet food manufacturing machine. The kernels are collected from the field, and then they grind it as a flour called cornmeal. After, the corn puff maker adds water and other raw materials to it for allowing a dough which is now prepared as well.

The dough is then transferred to the extruder, as well as the fish feed extruder machine produced by Jinan MT. It is just made to pass thought the long tube which serves in heating and molding (to form corn puffs). The corn puffs cool down after coming out of the extruder and are then bagged up for people to eat. The corn takes just one kernel and makes a delicious, crunchy snack many enjoy.

The Corn Puff Extruder Machine is primarily designed for making of corn puffs, the same as Jinan MT's pet food production machine. It has the ability to output massive volumes of corn puffs in an efficient manner for clients who want their products quickly. There is a motor in this machine that runs the device and buttons are installed on its control panel which helps operators to adjust the heat, speed as well pressure. that way they turn out crispy everytime just like a corn puff.

Specialized in RD and Corn puff extruder extrusions, with over 15 years of of history and 20000m2 factory Our equipment earns us a good standing on the market. We provide a complete turnkey service from raw material process to packing system, which includes MCC control system. The entire line of processing is an extremely high degree of productivity and automation. It is possible to customize the process according to customers' request.

We have a 20-year engineering team and hold numerous patents for food extrusion and other projects, such as a multi-choice low-power drying system, patented high accuracy extrusion machine, patented corn Corn puff extruder, patented full automatic packaging and stacking system.We offer production formula as well as installation and debugging services, as well as instruction for operators, up to the point that products are produced to your satisfaction.When compared to our competitors our product offers superior efficiency, energy saving superior quality with a competitive price as well as complete support before and after the sale.

Strong supply chain and production capacity as well as a variety of Corn puff extruder. Flexible and able to provide custom-designed services. Standards that are rigorous and independent and auditing procedures.

MT machinery provides excellent after-sales support international customers includes prompt responses clear Corn puff extruder technical support making sure any problems quickly resolved team dedicated professionals ready help any concerns questions quick efficient solutions proactive approach service resulted substantial increase customer satisfaction consolidated reputation trustworthy partner international trade focusing needs clients maintaining open lines communication MT machinery ensures clients receive best levels care support commitment excellent after-sales support improves buying experience customers also promotes positive long-term relationships them