make the delicious treats known as a chips, pretzels and breakfast cereal. Pet food machine price are significant, as they manufacture our preferred snacks in massive amounts making it continuously available to us.

You can create snack food with a Jinan MT breading extruder; so, what does an extrusion line for this type of product look like? It's pretty straightforward after all! The mix would be fed into the machine to start. The base for these corn puff

smoked or fried for preservation in original packaging. All of this happens pretty rapidly, which is why we have thousands of corn extruder to choose from at the store.

The manufacture of snacks was a tedious and boring job before

Some extruders can produce snacks that are in shapes as stars or animals, and the other for those require to have high-crunchy texture like some chips/snacks. For corn extruder machine, the possibilities are endless with so many different types of snacks out there for us to discover.

Our machine has achieved a Snack food extruder standing in the marketplace. We provide a turnkey service, from raw material processing to packing system, which includes MCC Control System. The entire process line is significant automation and energy efficiency. Any requests of the customer can be met.

A strong supply chain, a Snack food extruder and a variety of extrusion machines for food are all advantages. Flexible and able to offer custom-designed services. Standards that are rigorous and independent and audit mechanisms.

MT machinery provides outstanding Snack food extruder support international customers includes prompt responses smooth clear communication technical support ensuring issues can addressed quickly staff ready assist any inquiries problems providing quick efficient solutions proactive approach customer service resulted impressive increase customer satisfaction strengthened reputation trusted partner international trade focusing requirements clients keeping open line communication MT machinery ensures customers receive highest quality service support dedication outstanding after-sales services only improves experience customers purchasing us also fosters long-term friendly cooperation relationships them

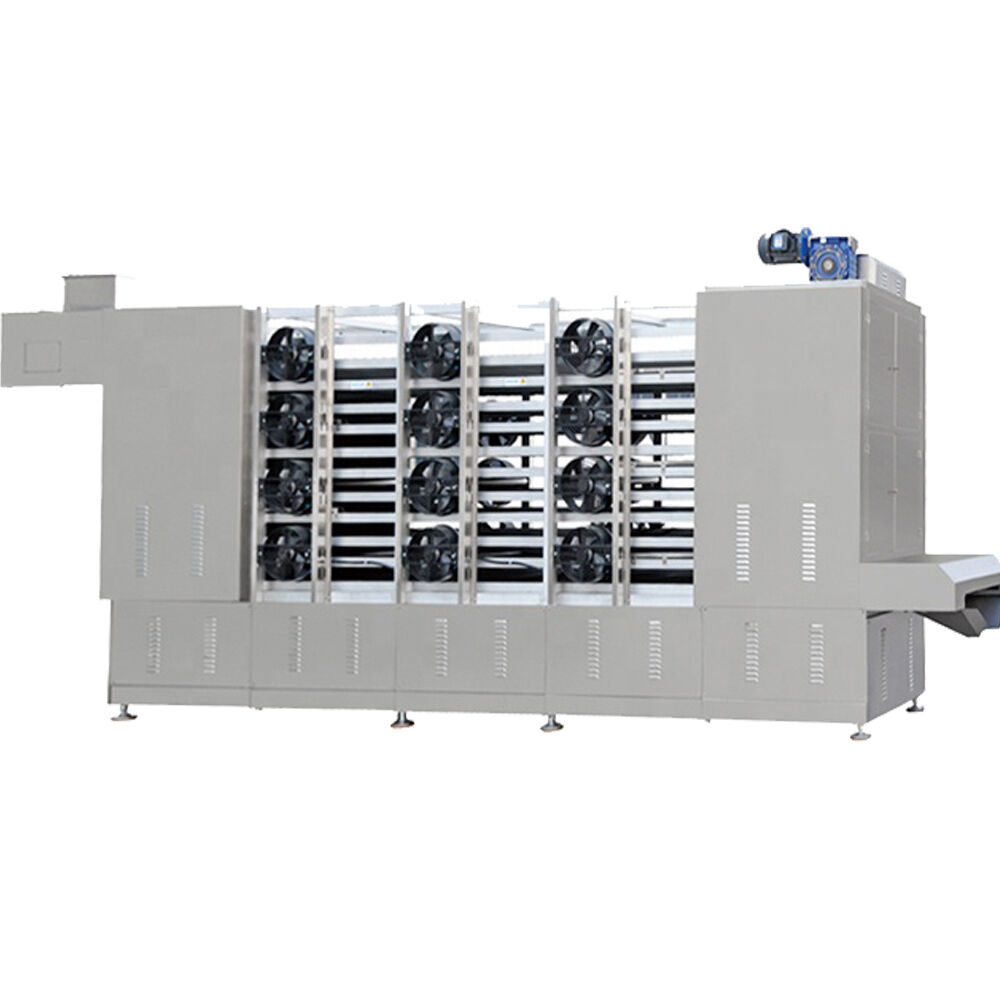

With more than 20 years of engineering experience, we have several unique patents related to food extrusion equipment and projects that include a multi-choice Snack food extruder drying system, high-precision food extrusion systems and a unique corn flattening machine with a complete automated packing and stacking system etc.We can offer formulas for production Installation and debugging assistance along with operator training, until products are manufactured to your satisfaction.Our solution has superior quality and value, as well being high in efficiency and energy savings.