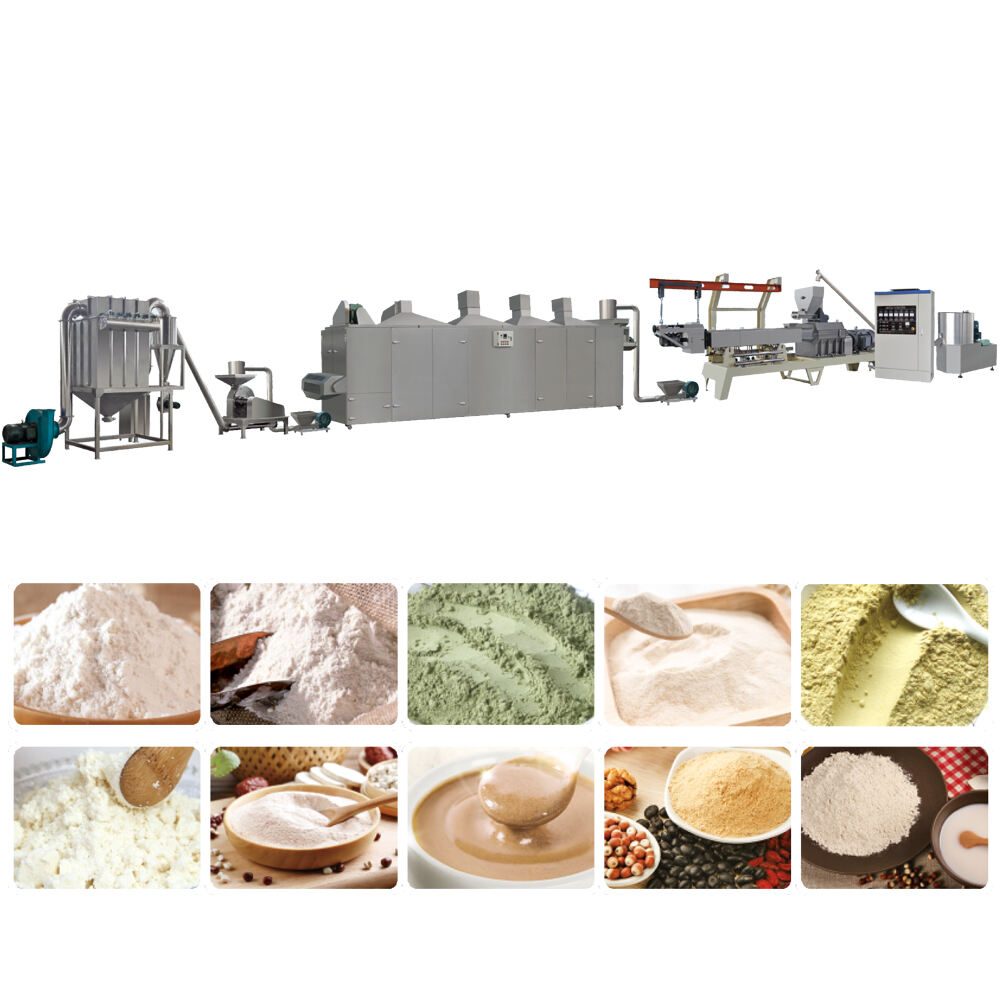

Corn is a very important plant grown in various parts of the world. There is little that was historically user-friendly about maize, but it can become some of the simplest and most popular foods people prepare for themselves each day. Corn—whether in premium organic popcorn, yummy cornflakes, or crispy tortilla chips—is present all throughout favorite savory indulges; a discovery with which I must admit the PhD clutching Sicilian and me were very familiar. But have you ever wondered how these delicious foods are made? They are actually made using a machine called a corn extruder that is pretty cool. Basically, with a corn extruder you take corn kernels and make many different products containing the overall food. The kernels are turned into cornmeal by grinding them too finely. This Jinan MT corn flakes making machine in india is but the first step. Then cornmeal was mixed with water and sometimes sugar or salt to form a dough. This dough, since it will be made into mouthwatering treats

Ready dough is loaded into the extruder. The dough is pushed and heated inside the extruder. As a result, the dough will start to puff up and sort of transform in its shape and texture. Corn as an ingredient, on its own being made into different types of foods is pretty exciting to think about. Meanwhile, the dough is mixed and heated in a very fast moving extruder. This fast progressing get blurry at its property and shape, as well making a special tasting point. When it is done, the extruder emits a finished product in whatever shape we desire — long strands for cornflakes or puffy shapes appropriate for snacks. Then, Jinan MT corn flakes machine price sliced into the correct size and carefully packed before being put away to sell in stores.

There are a wide variety of corn extruders on the market and each performs a different type of job. The first is called a screw extruder. A rotating screw forces the dough through, hot casing causes it to expand and set. Co-rotating twin-screw extruder: Another type, the co- rotating screw machine has two screws turn in same direction and ensures homogeneous mixing of dough and provide uniformity in temperature within final product. Another type is known as Counter-rotating Twin-screw extruders. This Jinan MT small corn flakes making machine has two screws running in opposite directions to mix it up and compact the dough differently.

This is also helpful in enhancing the flavor and nutrition of corn products. Food manufacturers can also do this by altering the heat, pressure and mixing- depending on what texture they want for their foods (soft, crunchy or chewy). Jinan MT corn flakes making machine price means that the snacks can be enjoyable to eat as well, where there is something for everyone

Furthermore, the corn flakes small machine price in india can help make corn products more digestible by our bodies and easier to gain important nutrients from them. Because the starch inside is easier for our human bodies to extract (partly broken down when heated and pressed). Our bodies can use the vitamins and minerals found in corn more efficiently, which keeps them healthy.

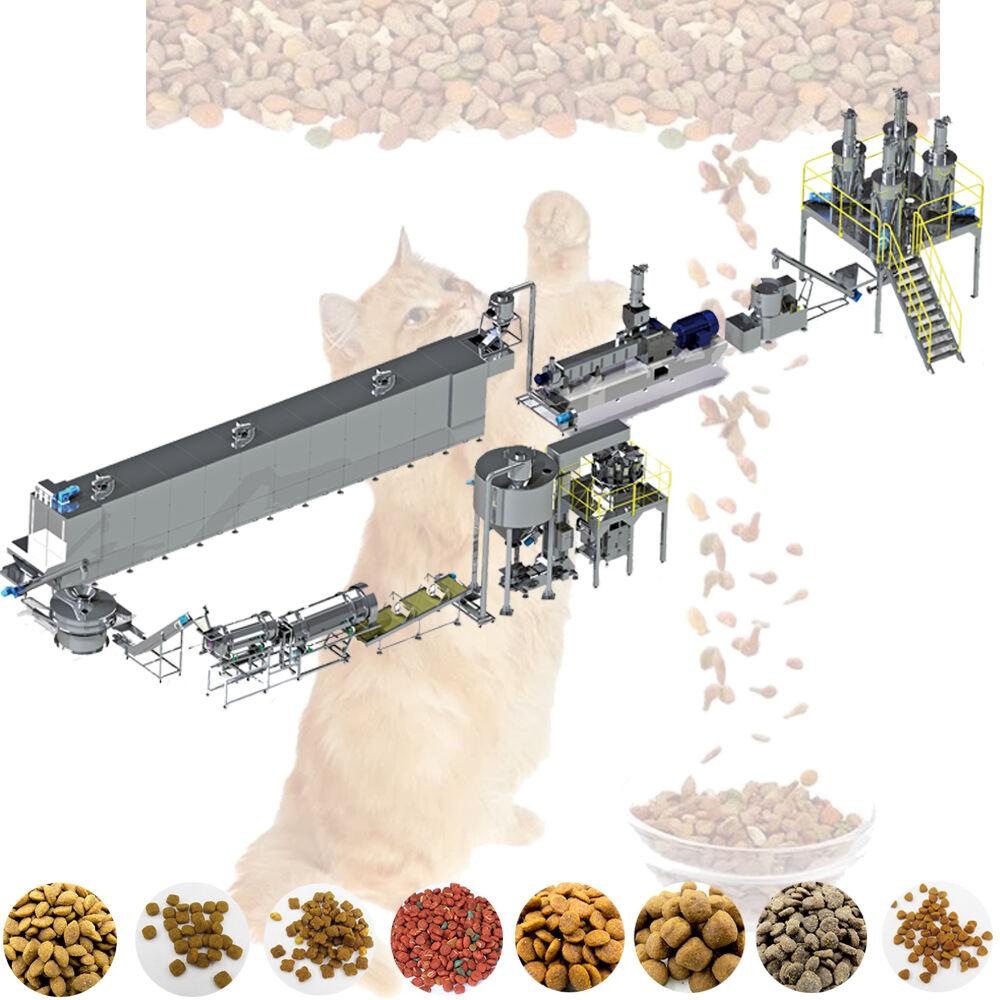

Our machine has gained great standing in the marketplace. We offer a complete Corn extruder, from raw material preparation to packing systems, including MCC Control System. The entire processing line has high productivity and automation. Any requests of the customer can be taken care of.

A Corn extruder supply chain, a huge production capacity, and a wide range of extrusion machines to make food are the main strengths. Flexible and able to offer personalized services. They have strict and independent standards and auditing procedures.

With over 20 years of experience in the engineering team, we own several unique patents related to food extrusion equipment and projects that include a Corn extruder low energy consumption drying system, high accuracy food extrusion system the corn flatten machine, unique with a complete automated packaging and stacking system, etc.We offer production formula, installation and debugging service as well as operator training, until you are completely satisfied with the products we produce. satisfaction.Our solution has superior quality and price, as well with a high degree of efficiency and energy savings.

MT machines provide excellent after-sales services to its international customers this includes prompt responses clear and seamless communication as well as technical support making sure that any problems can be solved quickly our experienced team is willing to assist you with any inquiries or problems with quick and effective solutions this proactive service approach has resulted in a substantial improvement in satisfaction of our customers and has helped us establish our status as a trustworthy partner for international trade by Corn extruder on the demands of our customers and maintaining open lines of communication MT machinery ensures that our customers receive the highest levels of care and support this dedication to superior after-sales service not only improves the purchasing experience for our customers and creates a friendly long-term relationships with them