Do you like snacks that are lightly crispy? Ever wonder how these tasty treats are made? Well. Have you ever wonder how your puffed favourites comes to life, looks like it is a nothing less than magic but then the reality check happens in our minds and we all also know more or else about Puffed food extruder machines, you are in luck, similar to the Jinan MT's product like pet food extrusion process. Read on for more details.

Puffed food Extruder machines are so good that they changed the way we imagine about snacks because of its light and puffy attributes, identical to dog feed making machine innovated by Jinan MT. But how do they do this? It all begins with a unique process. They press a mixture of grains (ground rice, corn) and water under pressure through small holes. And that leads to heat, which when you are trying to make your own snack is one of the key things needed. This is followed by a very rapid cooling of the batch. In a few, the mixture will puff up and crisp. Isn’t that cool?

There are infinite numbers of possibilities you can make with a puffed food extruder machine, same with Jinan MT's cat food manufacturing process. Yes you may make variety of yummies such as puffed rice, corn snacks, cheese balls and even to snack for your pets which is dog food. Not only are these snacks tasty but easy when on the go. You can use them as a small meal when you need to eat something or have it instead of dry snacks between two regular meals. They are great for playdates, school lunches or movie night at home.

There is some neat that goes on inside a puffed food extruder machine, to create all these tasty treats, as well as the cat food making machine innovated by Jinan MT. The mixture is heated and pressurized inside the machine, in a special chamber. The mixture (when pushed out this small gap) expands and becomes lighter, fluffier and very tasty. This innovative process is what brings you all the puffy snacks that you know and love.

The great thing using a puffed food extruder machine, is that you can be so creative, just like the Jinan MT's product called fish feed floating pellet making machine. Your mixture can take a variety of flavors and ingredients. So if you want cheesy puffs, just add some cheese powder and sprinkle it. If you are feeling something sweet, cocoa powder will give the “magic” making chocolate puffs. You could even sprinkle some dry fruit or nuts for a cheeky take on traditional snack favourites. With so many genres to choose from, you can create something unique with every episode.

MT machinery provides Puffed food extruder machine after-sales service international customers including prompt responses smooth clear communication technical support ensuring any issues resolved efficiently experienced team is hand assist any inquiries problems providing swift effective solutions proactive approach service has led impressive increase satisfaction customers consolidated reputation trusted partner international trade MT Machinery committed providing highest possible service support customers focusing needs keeping communication channels open commitment exceptional after-sales services not only improves buying experience customers but helps build long-lasting relationships cooperation them

We have a 20-year team of engineers and own many patents for food extrusion equipment and projects. These include a multi-choice low power consumption drying system Puffed food extruder machine high accuracy extrusion machine, patented corn flattening equipment, patented complete automatic stacking and packaging system.We offer production formula, installation and debugging service along with operator training, until products are produced to your satisfaction.Comparing with our competitors, our solution has superior efficiency, energy saving, superior quality affordable price, as well as complete support before and after the sale.

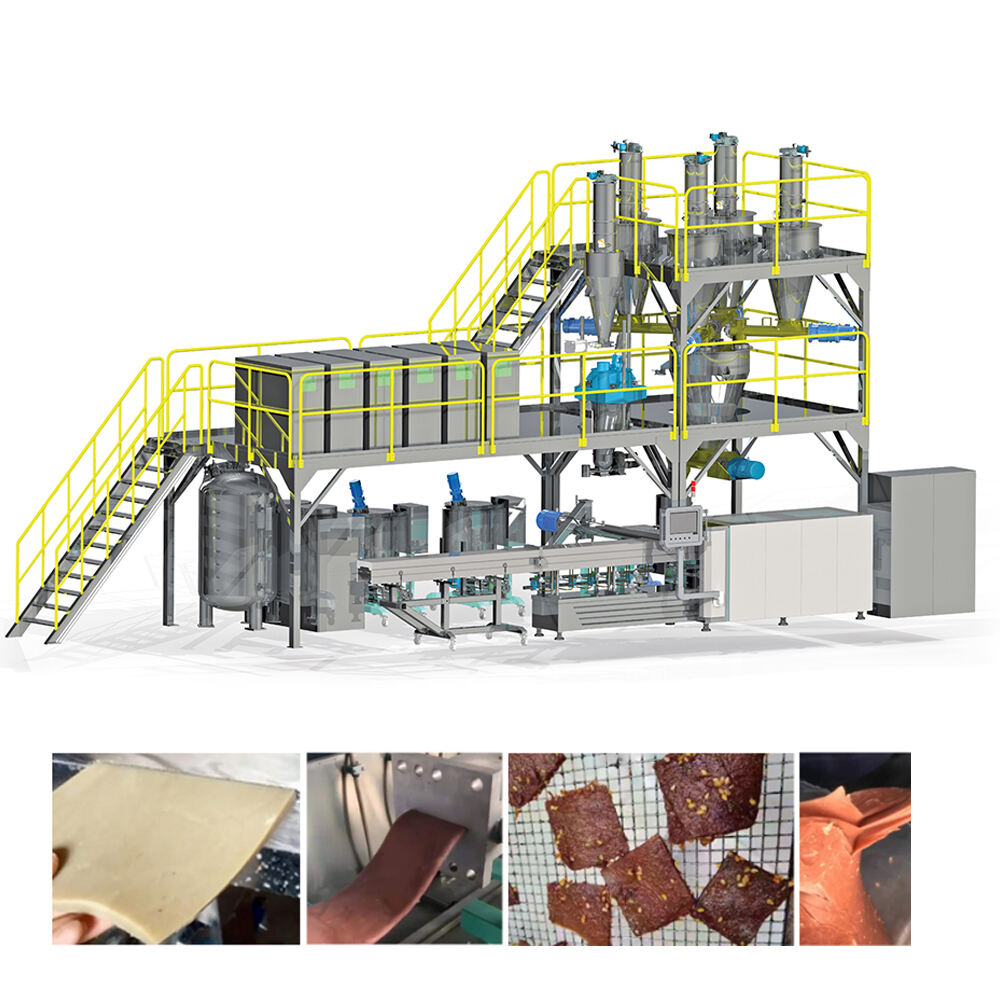

Our equipment has built a strong recognition in the marketplace. We provide a turnkey service, from raw material preparation to Puffed food extruder machine, with MCC Control System. The entire process line is an extremely high degree of productivity and automation. The customization is based on the needs of the customer.

A solid supply chain, a huge capacity for production and a range of extrusion machines to make food are the main strengths. Flexible and capable of offering Puffed food extruder machine. They have strict and independent standards and audit methods.