If you are a pet owner then your pets food is probably often on your mind. It certainly is interesting to think about what it takes to make the food that makes our furry pals full and fit. Part 1: Extrusion The pet food machine most overlooked and ignored method to prepare pet foods is called ‘Extrusion’. In this article, we shall discuss the extrusion process used to make pet food and why that is critical in maintaining a high level of quality.

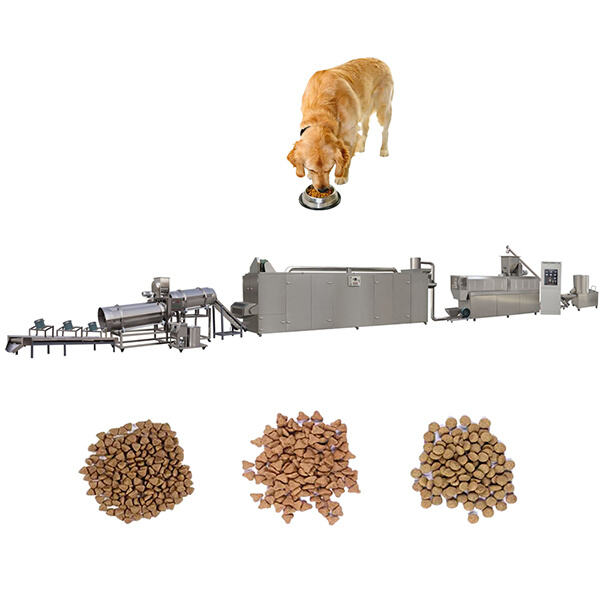

Extrusion is a unique process used to produce many types of foods, including pet food. The Jinan MT ingredients are loaded into a large machine, which mixes them and extrudes the mixture as small pieces. Again, that shaping takes place using heat (to soften) and pressure coupled with a form of machine known as an extruder. The extruder is quite crucial as it kind of works the food items and offers them that shape we observe in pet foods.

Extrusion is a key step in producing high-quality pet food. During extrusion, the ingredients are slightly broken down by heat and pressure used. This is great for your pet, making the food easier to digest and that will make a huge difference in how they feel. This Jinan MT additionally aids in cleaning the food of your four-legged companion.

Similarly, the caliber of the components found in doggie food is similarly crucial to guarantee that a wonderful brand ends up being healthier. Nutrient-Rich: Quality ingredients that give your animal the vitamins, minerals and other nutrients he or she needs to live healthier life entirely. He needs to check the pet food extruder machine ingredients list when purchasing pet food. Search for meals that include authentic meat, veggies as well as new fruits. Look for pet foods that contain few fillers and by-products, since these are mostly devoid of nutritional value.

Pressure in the Jinan MT extruder matters a lot too. It helps in maintaining a strong texture of the pet food so that it does not easily break apart into pieces. Not only is this pet food extrusion machine nice and a different texture, but it makes chewing more fun for the pet. And it also maintains its freshness and taste, considering food across a longer span of time.

You need to choose the right ingredients and use good extrusion method in making perfect pet food! Whole, Real Ingredients- One of the keys to quality pet food The best pet weight-reduction plan consists of the natural pets meals with complete meal styles, clean greens and fruits that have no longer been overly processed. This pet food processing machine can really make a difference in the bit of nourishment that your pet gets.

The manufacturing of pet food cannot be compromised when it comes to safety and efficiency. Workers have to be skilled in their operation of the extrusion machines. And secondly, they pet food making machine price have to make sure it is all kept hygienically clean so no nasty bacteria gets in their food. 6- Good hygiene practices in food production.

Our machine has gained great standing in the marketplace. We offer a complete Pet food extrusion process, from raw material preparation to packing systems, including MCC Control System. The entire processing line has high productivity and automation. Any requests of the customer can be taken care of.

We have a 20-year team of engineers and own many patents for food extrusion equipment and projects. These include a multi-choice low power consumption drying system Pet food extrusion process high accuracy extrusion machine, patented corn flattening equipment, patented complete automatic stacking and packaging system.We offer production formula, installation and debugging service along with operator training, until products are produced to your satisfaction.Comparing with our competitors, our solution has superior efficiency, energy saving, superior quality affordable price, as well as complete support before and after the sale.

MT machines provide excellent after-sales services to its international customers this includes prompt responses clear and seamless communication as well as technical support making sure that any problems can be solved quickly our experienced team is willing to assist you with any inquiries or problems with quick and effective solutions this proactive service approach has resulted in a substantial improvement in satisfaction of our customers and has helped us establish our status as a trustworthy partner for international trade by Pet food extrusion process on the demands of our customers and maintaining open lines of communication MT machinery ensures that our customers receive the highest levels of care and support this dedication to superior after-sales service not only improves the purchasing experience for our customers and creates a friendly long-term relationships with them

A solid supply chain, a huge capacity for production and a range of extrusion machines to make food are the main strengths. Flexible and capable of offering Pet food extrusion process. They have strict and independent standards and audit methods.