There was a puffed food extruder in the market. It used to have a cool beeping beast that belched glistening popcorn, and sugary crunchy cereals swamps. Tagbireyyou is an intriguing instrument that helped cook dishes like on this day love a lot.

A puff food extruder — A machine that will make your stuff super puffy and light, as well as the Jinan MT's pet food processing line. It accomplishes this through pressure, heat and a smidgen of water. This is a process in which machine passing grains that are (small edible part of food: other ingredient) through small holes. As it pops, our tasty popcorn appears through these holes in the ceiling as snacks.

In addition, the puffing food extruder uses a certain proportion of water, flour and other materials to production delicious foods, along with the noodles manufacturing machine built by Jinan MT. As you continue to crush, it will form a dough that can be pressed through the pasta maker. They are passed through a thin tube with small holes at one end. Its expanded and puffed snacks are still traveling in the pipe. And here is where all of the magic happens.

The puffed food extruders are amazing application since you can process any the tiny snacks with all its applications, as well as the Jinan MT's extruder machine in food industry. For example they can highlight cereals such as Cheerios or Kix and additionally are able to make novelty snacks including popcorn baskets, rice cakes cubes like an ingot of metal puffed up from a tool cheese puffs on main street even veggie crisps. But slice them up differently and mix the ingredients together, you get all sorts of cool finger foods that suit each persons taste.

But before you jump to extruders for puffed snack production, well, think again because these machines are versatile enough to produce animal feed; eco-friendly packaging and medical devices, same with the dog food making machine from Jinan MT. By changing how a puffed food extruder functions, as well as the ingredients it processes, you can manufacture a wide range of valuable products. It puts into perspective how invaluable a single good machine can be.

Which reminds you, these machines are wonders and can make so many different things, similar to the Jinan MT's product like protein bar extruder machine. What the results are even better sounding, though: While chips and wonton wraps get us to some unique finger foods that would be hard to look together. It is also available the puff food maker for yummy snacks not only to people, but it helps in development of another useful things that we need.

MT machinery provides excellent after-sales support international customers includes Puffed food extruder inquiries clear concise communication technical assistance ensuring any issues can quickly addressed team dedicated professionals available assist questions issues offering quick effective solutions proactive approach customer service resulted substantial increase customer satisfaction increased standing reliable partner international trade MT machinery offers best possible service support customers focusing needs maintaining open lines communication commitment providing exceptional after-sales services only improves experience customers purchasing us also helps build long-lasting relationships cooperation them

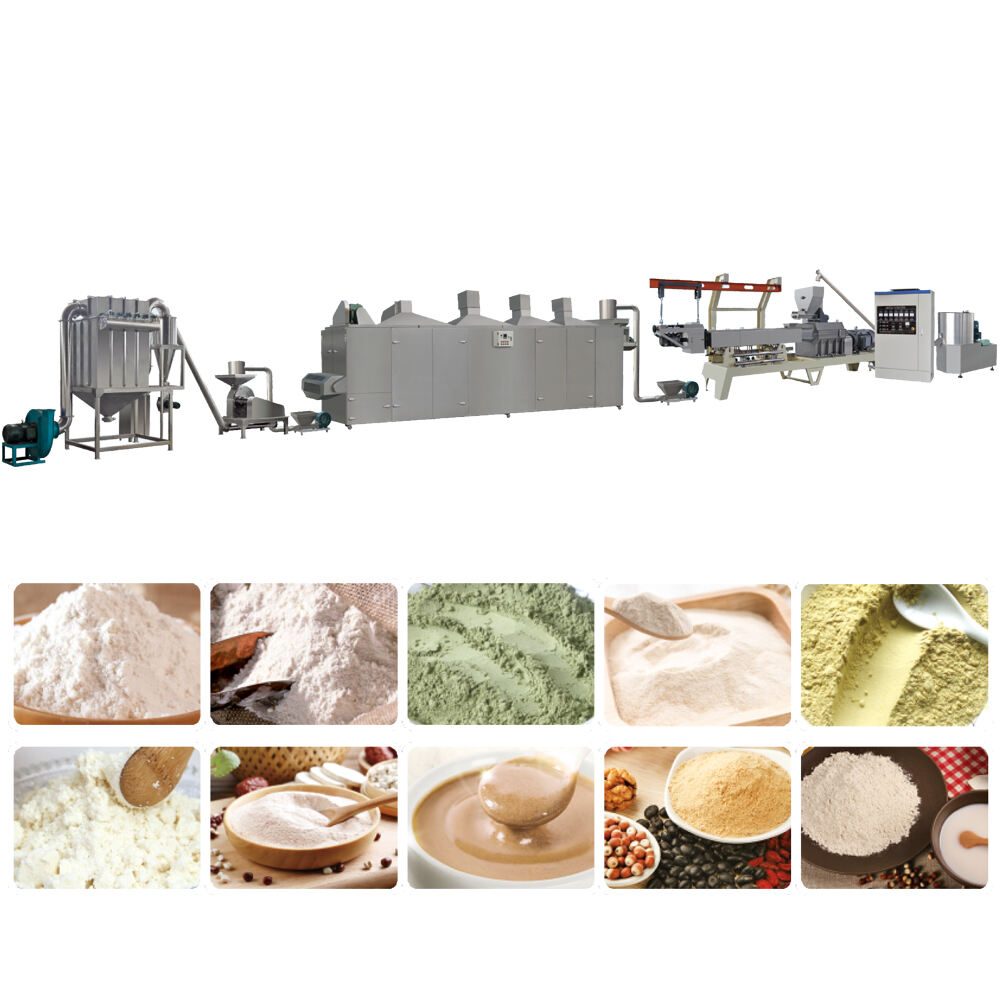

Puffed food extruder in RD and food extrusion projects with more than 15 years of history and a factory of 20000m2, our machine gains great popularity on the market. We provide complete turnkey solutions from raw material to packing system, which includes MCC control system. The entire process line is significant productivity and automation. Any customization can be made according to the needs of the customer.

We have a 20-year engineering team and hold numerous patents for food extrusion and other projects, such as a multi-choice low-power drying system, patented high accuracy extrusion machine, patented corn Puffed food extruder, patented full automatic packaging and stacking system.We offer production formula as well as installation and debugging services, as well as instruction for operators, up to the point that products are produced to your satisfaction.When compared to our competitors our product offers superior efficiency, energy saving superior quality with a competitive price as well as complete support before and after the sale.

A solid supply chain, a large production capacity, and a wide range of extrusion machines for food are all strengths. Can provide custom-designed solutions and a lot of flexibility. They have strict and independent standards and Puffed food extruder methods.