Did you think how your favorite snacks are made. It’s interesting. The kind of machines used to make all the yummy starchy foods we love (chips, cereals, even pasta) is called an extruder. This wonderful appliance makes use of natural ingredients to create many types of delectable treats. Most people are not aware that food companies employ extrusion to make all things crispy and starchy (well, no surprise — think potato chips) as well as pet foods.

What then, is the functionality of this extruder? This is a bit like squeezing toothpaste out of the tube, similar to the Jinan MT's product like pet food processing machinery. Into a large hole called hopper, the raw ingredients are poured in at first. It is how the first spark begins. The machine then takes this mixture and applies a large amount of pressure to it before squeezing the ingredients out through an opening at the very end. The mixture is squeezed and cooked over a hot chamber. Then it is chopped into small eating sized pieces.

It is not only convenient but a lot quicker than other ways of making food and for the most part, you will only need an extruder machines, just like the pet food processing machines made by Jinan MT. In a similar sense, more chips he develops in less time and with lower costs on thousands of machines like this one would allow food companies to pour out even more snacks per month. It is beneficial as it saves the money of companies and they can provide snack to more peoples in short periodionate.

Extruder machines are also useful for raising efficiency and cutting out wastage. Using new or cleaned equipment there is an incredible incentive to run a generous deadweight toll with most processors that three fourths of the center crude fixings will readily be made into nibble source due to those machines have been designed inside place and process every bit from claiming it. And it is not only a good thing for the businesses, but also our planet. Through waste minimisation, it keeps the environment a little bit cleaner and can reduce overflow disposal costs.

If you are extruder machines, they creativity,,, They help food companies produce novel and interesting snacks that may not have been feasible to make before, along with Jinan MT's product noodles manufacturing machine. For instance, in the way they produce snack options of animal or 3D forms. Especially when it comes to fun character looking snacks that kids love so much. With different kinds of flavors, they can also be more attractive to anyone who has it.

The Extruder machine has proved to be a invention for the food industry, same with the kurkure machine price supplied by Jinan MT. These machines make many food products much quicker and more uniformly than traditional methods. Through this technology, businesses can offer a wide range of new and unique snacks to consumers that they would not otherwise be able to make. This innovation means people have more choice.

It can produce healthy as well tasty snacks from extruder machines, along with Jinan MT's product snack extruder machine for sale. Food companies can play a positive role by making snacks with healthier varieties of ingredients such as whole grains and vegetables that make it easier for people to choose them. It is great to have these snack ideas on hand as they are still delicious and add more nutrients than just empty calories (which is important because we need our nutrition).

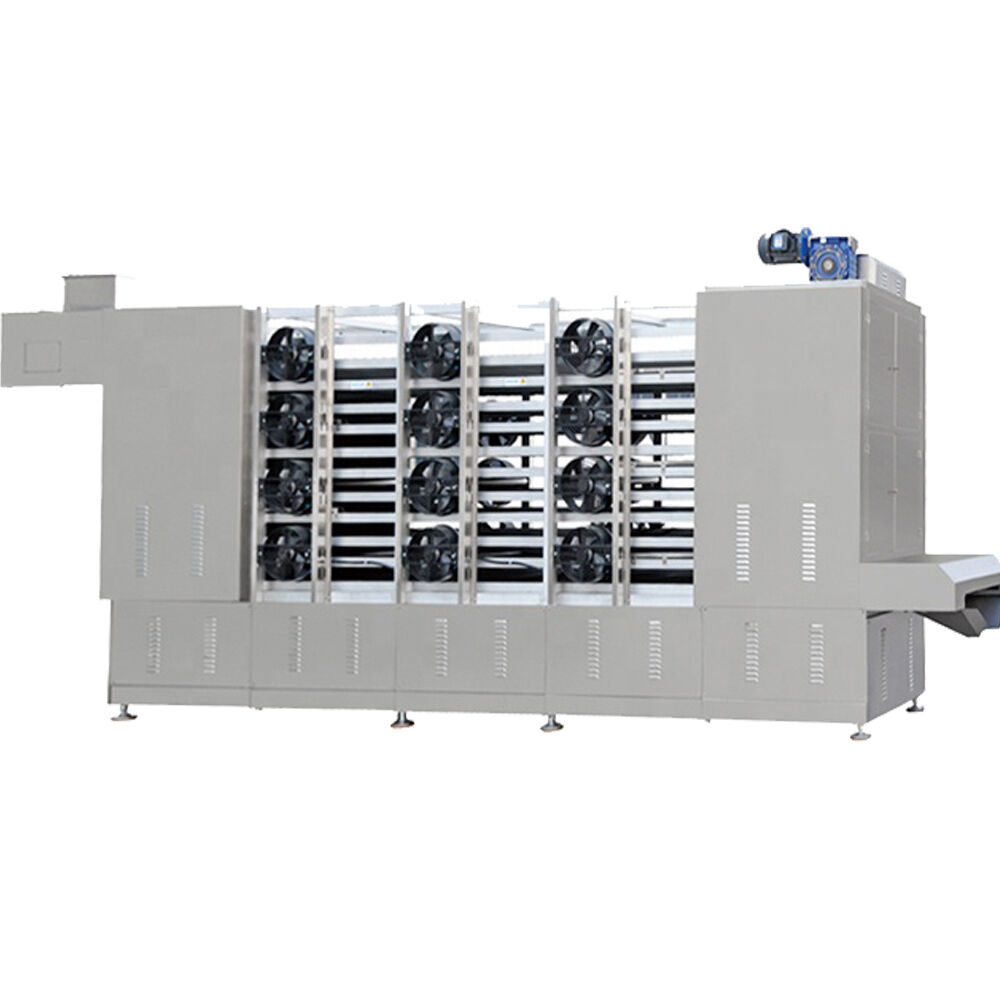

Specialized in RD, manufacturing of food extrusions, with over Extruder machine in food industry of of experience and 20000m2 of factory space Our machine has a great reputation on market. We offer a turnkey solution from raw material to packing system using MCC control system. The whole processing line has high automation efficiency, energy efficient and high efficiency. Customer's requests are accommodated.

With over 20 years of experience in the engineering team, we own several unique patents related to food extrusion equipment and projects that include a Extruder machine in food industry low energy consumption drying system, high accuracy food extrusion system the corn flatten machine, unique with a complete automated packaging and stacking system, etc.We offer production formula, installation and debugging service as well as operator training, until you are completely satisfied with the products we produce. satisfaction.Our solution has superior quality and price, as well with a high degree of efficiency and energy savings.

MT machinery provides outstanding Extruder machine in food industry support international customers includes prompt responses smooth clear communication technical support ensuring issues can addressed quickly staff ready assist any inquiries problems providing quick efficient solutions proactive approach customer service resulted impressive increase customer satisfaction strengthened reputation trusted partner international trade focusing requirements clients keeping open line communication MT machinery ensures customers receive highest quality service support dedication outstanding after-sales services only improves experience customers purchasing us also fosters long-term friendly cooperation relationships them

A Extruder machine in food industry supply chain, a huge production capacity, and a wide range of extrusion machines to make food are the main strengths. Flexible and able to offer personalized services. They have strict and independent standards and auditing procedures.