It is essential because in this way, all of the natural raw ingredients are converted into delicious and nutritious meals for our pet. Today we will concentrate on how pet food is manufactured and the special equipment, applications of it used to guarantee that our furry little much-loved buddies are supplied with safe catered for food.

The Jinan MT dog food making machine begins with the choice of good raw materials for them. This is because these ingredients are good and have a high reference value. Once the ingredients are chosen, they measured in specific quantities that would provide a balanced meal to pets. A healthy and happy pet needs a well-balanced diet. If pets eat what they are intended to be eaten, that energy will unlock the potential for them to play more, grow better and live fuller.

While preparing pet food many steps are involved and need attention. The foods we feed our pets are closely monitored every step of the way to ensure that they are safe for consumption. The factory is hygienic and without germs or contamination during production of the food. Cleaning is the best way to keep it as nutrient-packed food. These machines also need cleaning-solving design. This allows the workers to clean these machines fast and efficiently, so that we can contribute with our healthy food for pets.

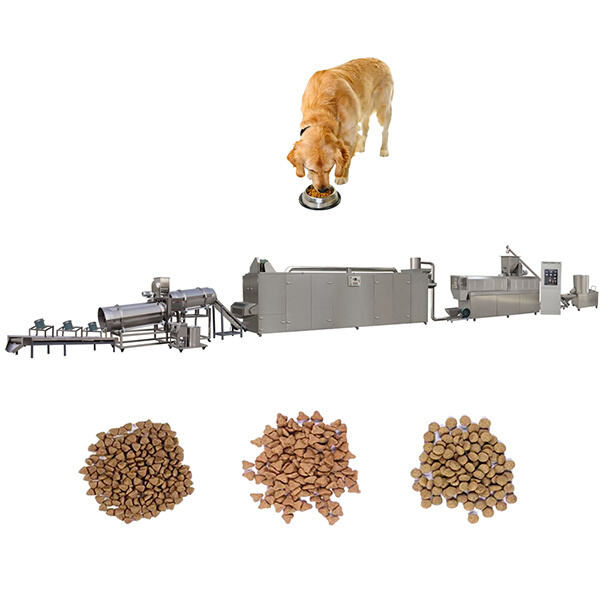

The Jinan MT production of pet food requires machinery that is designed specifically to manufacture foods the pets also like. When using these machines, the pet food is measured correctly into each package and moved along a line where it mixes with other contents of that brand before being cooked in its own bag. This ensures that the food is cooked at an optimal temperature and for just the right amount time to preserve all of its precious nutrients. It also come along sensors in the machines to find out any issue during preparation of these food items. These sensors are great because they let workers know if there is an issue. This way they can address any problems before becoming an emergency and ensure that the food is always safe/elicits a positive response in animals.

Pet Food: Franchisees benefit from distributing an extensive selection of high-quality, nutritionally-balanced pet food manufactured by a team of PhD-trained professionalsupatenprocessors They develop meal plans from scratch that makes pets receive the necessary nutrients for them to live a quality life. To do this, they also look into the varying requirements for pets according to their age, breed and health. For instance, puppies may require various supplements than developed mutts. Taking all of these factors as well as the quality of dry dog food making machine into consideration helps to ensure that the pets receive a food which is both appropriate for their species and will be natural in its final form, life-stage style so that way they can live long healthy lives full of fun.

Number one is developing a quality pet food. People think of this as the bare minimum but it really does come to make your pet happy when they are being fed good products consistently.

The pet food production line performs efficiently since it is made with smooth operation design. This plan guarantees that the nourishment is constantly solid. At the production side, machines are used in-line to reduce waste and work very accurately. Most processes require their computers as controls to reduce the inevitable faults. Not having proper Jinan MT dog food processing machine quality might taint our food. It ensures that pets receive the highest quality of food every time.

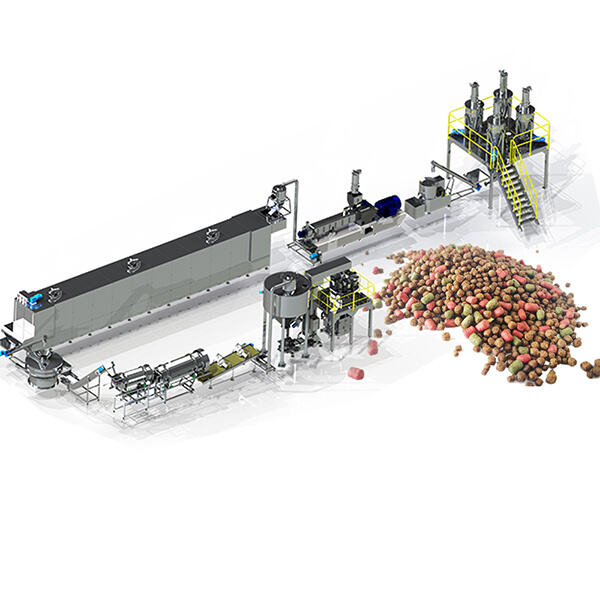

Specialized in RD and Pet food production line extrusions, with over 15 years of of history and 20000m2 factory Our equipment earns us a good standing on the market. We provide a complete turnkey service from raw material process to packing system, which includes MCC control system. The entire line of processing is an extremely high degree of productivity and automation. It is possible to customize the process according to customers' request.

MT machines provide excellent after-sales services to its international customers this includes prompt responses clear and seamless communication as well as technical support making sure that any problems can be solved quickly our experienced team is willing to assist you with any inquiries or problems with quick and effective solutions this proactive service approach has resulted in a substantial improvement in satisfaction of our customers and has helped us establish our status as a trustworthy partner for international trade by Pet food production line on the demands of our customers and maintaining open lines of communication MT machinery ensures that our customers receive the highest levels of care and support this dedication to superior after-sales service not only improves the purchasing experience for our customers and creates a friendly long-term relationships with them

A solid supply chain, a large production capacity, and a wide range of extrusion machines for food are all strengths. Can provide custom-designed solutions and a lot of flexibility. They have strict and independent standards and Pet food production line methods.

We have a 20-year team of engineers and hold Pet food production line for food extrusion equipment and projects. These include a multi-choice low power consumption drying system and patented high-precision extrusion technology, patent-pending corn flattening equipment, patented full automatic packaging and stacking system.We offer production formula, installation and debugging service, as well as instruction for operators, up to the point that products are produced to your satisfaction.Our solution has superior quality and pricing, as as high levels of energy efficiency and savings.