Well, dog food is not made in the magical land of where-dogs-get-their-food but rather in a factory called Dog Food line. Ever thought about where all the ingredients in dog food come from? Well, it all starts on farms. A farmer produces different products such as cereals, vegetables, and fruits—some of which will be combined to form a kernel-based dry dog food. Once the farmers harvest these ingredients they are picked, packed and taken to a dog food factory where it will be complied in your furry friend's dining.

When the ingredients make their way to our dog food factory, a team of natural nutritionists takes over, as well as the pet food machinery manufacturers by Jinan MT. The people who work in this field are called nutritionists, and they have a very important job. Then they just mix and measure all the different ingredients to make yummy dog food also good for your dogs. You will find that they want to provide the food with enough protein, fats thiamine and minerals in general. It is done so as to keep your dog young, playful and energetic. The experts test not only the nutrients inside but also that whether this flavor is favorable for your dog and how easily his teeth are capable of chewing.

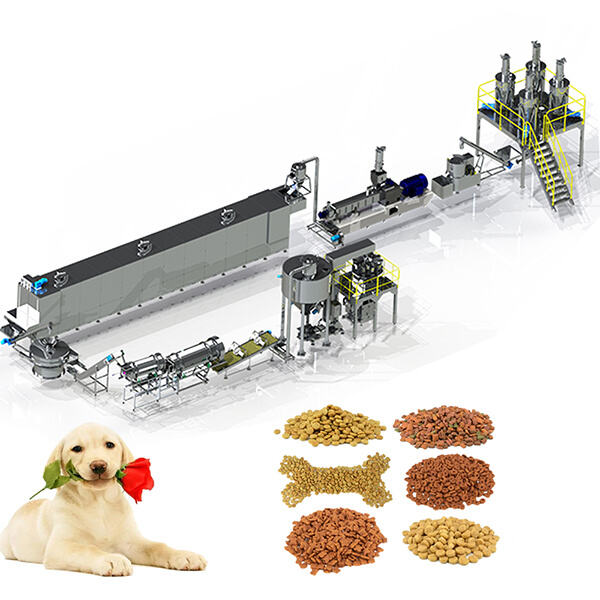

Today dog food making factories use machines to help make the food as perfect every time, along with Jinan MT's product pet food extrusion process. There are machines that mix, bake and package the dog food for example. There are also other machines for checking the ingredients to ensure they make safe food. These machines are mainly used to make the tastiest and healthiest dog food for man's best friend. This means, you can feel good about what you are giving your pet.

The safety of any dog food is paramount, just like the animal feed pellet machine developed by Jinan MT. Every ingredient that arrives at the factory is tested for purity and presence of harmful substances before it can be processed into product. The production is a completely clean machine that continuously maintains cleanliness the food does not have any germs or dirt in it. The whole production line is checked at every point to ensure the dog food is packed well, tightly sealed and fresh enough for your furry friends will love it.

Sustainability is another highly relevant issue in dog food production, along with Jinan MT's product cereal extruder. As for sustainability, it is responsible for the environmental and non-damaging processing of resources. That might in the production of dog food, use any material for packaging. It can also mean using local farms as a source for their ingredients in an effort to reduce the carbon footprint or pollution caused by transporting goods. And as a results, there are now some dog food factories that collect waste from the production and recycle it to produce energy what is another positive thing done for our planet.

Dog food production line in RD and food extrusion projects with more than 15 years of history and a factory of 20000m2, our machine gains great popularity on the market. We provide complete turnkey solutions from raw material to packing system, which includes MCC control system. The entire process line is significant productivity and automation. Any customization can be made according to the needs of the customer.

A solid supply chain, a large production capacity, and a wide range of extrusion machines for food are all strengths. Can provide custom-designed solutions and a lot of flexibility. They have strict and independent standards and Dog food production line methods.

MT machinery provides excellent after-sales support international customers includes Dog food production line inquiries clear concise communication technical assistance ensuring any issues can quickly addressed team dedicated professionals available assist questions issues offering quick effective solutions proactive approach customer service resulted substantial increase customer satisfaction increased standing reliable partner international trade MT machinery offers best possible service support customers focusing needs maintaining open lines communication commitment providing exceptional after-sales services only improves experience customers purchasing us also helps build long-lasting relationships cooperation them

With more than 20 years of engineering experience, we have several unique patents related to food extrusion equipment and projects that include a multi-choice Dog food production line drying system, high-precision food extrusion systems and a unique corn flattening machine with a complete automated packing and stacking system etc.We can offer formulas for production Installation and debugging assistance along with operator training, until products are manufactured to your satisfaction.Our solution has superior quality and value, as well being high in efficiency and energy savings.