Ever dream about where your pet's food comes from? Jinan MT dog food manufacturing process is creating meals for your pooch! In this blog, we will focus on what happens before the pet food ends up in your fur baby's bowl.

Every pet food company is on a quest to find the best ingredients for better, healthier products. They all want to ensure that pets receive everything necessary for a happy and healthy life. Grain free dog food is also one of the most popular type of pet products that many pets owner prefer in providing for their pets. This food is free of corn, soy and wheat. This is an important concern because, in some pets, these are grains that can cause indigestion and make them feel sick! Instead, grains are substituted with other wholesome pet favorites like potatoes and (sometimes) meats pets love less Chomping into a bowl of grain free dog food is fun for you pup. This ensures that pets can eat without experiencing any nausea or stomach problems.

Not only is making dog food that tastes good an art, it's a science. When companies create new pet food, there are so many things they have to take into account. From selecting the best possible ingredients to making sure everything has just the right texture, Jinan MT dry pet food manufacturing process get pretty serious about it and think long and hard about what flavors cats or dogs would respond most positively. Many pets food manufacturers actually taste-give their things, whether by other domestic animals and cause the pleasure is criteria before it goes to pet maintenance supplies stockpiling. This allows them to be certain as the food isn't just healthy, but also something pets would absolutely want.

In order to make food safe for our pets, follow many strict regulations about the production of pet feed. The FDA, or Food and Drug Administration, is responsible for ensuring that pet food is safe to eat. They established significant guidelines on the type of ingredients that can be used and how the food is cooked. It is certainly strict for pet food companies to ensure they are not getting killed with the Queen of Hearts blade. They will also have to test their Jinan MT dog food manufacturing process to ensure they comply with certain nutritional requirements. As a result, pets receive their necessary vitamins and minerals to remain healthy.

Real Good Food is an example of a pet food company working towards sustainability. They are using all parts of their produce in some very innovative ways to create less waste and be friendlier on the environment. Moreover, it also plays a significant role in protecting our planet from unwelcome waste. Lots of people are also highly incorporating the sustainable packaging that is best for your ground. A good instance is the use of biodegradable packaging for companies (from corn starch) that can decompose over time and do not pollute the environment. That way, they are not just becoming pet owners but also caretakers for the Earth.

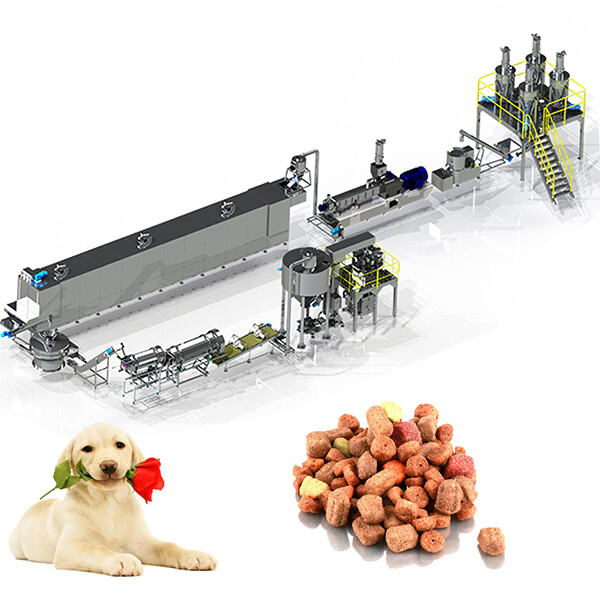

Specialized in RD, manufacturing of food extrusions, with over Pet food manufacturing process of of experience and 20000m2 of factory space Our machine has a great reputation on market. We offer a turnkey solution from raw material to packing system using MCC control system. The whole processing line has high automation efficiency, energy efficient and high efficiency. Customer's requests are accommodated.

MT machinery provides outstanding after-sales Pet food manufacturing process international clients includes quick responses smooth clear communication technical assistance ensure any issues solved quickly team experts available assist any issues questions offering quick effective solutions proactive approach customer support has led to increase customer satisfaction cemented status reliable partner international commerce focusing demands clients keeping lines communication open MT machinery ensures customers receive highest level support care dedication outstanding after-sales service not only enhances customer purchasing experience also builds long-term relationships friendship them

Pet food manufacturing process have a 20-year team of engineers and hold numerous patents for food extrusion equipment and projects. These include a multi-choice low-power drying system, patented high accuracy extrusion technology, patent-pending corn flattening machine, patented fully automated stacking and packaging system.We offer production formula installation and debugging, as well as instructor training, up until our products are made to your satisfaction.Our solution offers superior quality and cost, as well as a high level of efficiency and energy savings.

A strong supply chain, an enormous production capacity, and a Pet food manufacturing process of extrusion machines for food are all strengths. Able to provide customized services and strong flexibility. Standards that are rigorous and independent and auditing procedures.