About Extruder, then what an extruder? An extruder is a machine specifically designed to convert grains or even vegetables from their natural form into something we can consume. This happens by mixing the components, cooking them and then pushing the mixture through a small hole. The idea is that the snack will appear and taste like every other time it was produced, an important consideration since a customer wants to receive what meets their expectations or they are not happy.

There are extruders that can make a whole host of food items, as well as the Jinan MT's instant noodle machine. They are very versatile. They can, for instance, convert grains into cereal or even nuts: Smooth peanut butter to dream about; transforming raw vegetables content since yummy Noodles. These raw ingredients are converted into snacks that taste good and have a texture just the way we feel like by extrusion process.

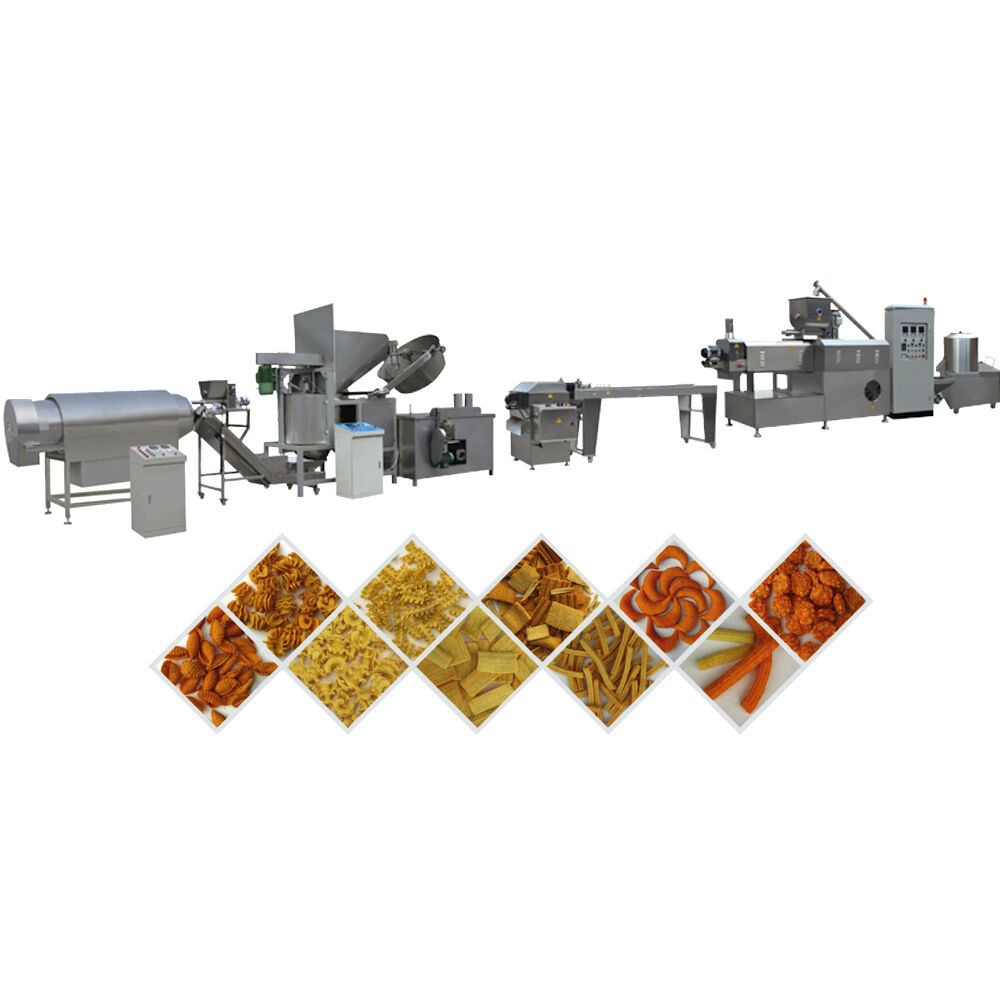

Here's how it goes. An example of an interesting manufacturing process is extruders that use the production method to make crunchy snacks such as cheese puffs and pretzels. So basically you mix the ingredients together, cook it in an extruder and shape fun little shapes that we like to eat. The size of the snack is being determined in filling and then shape it by extruder for its own crispy delicious flavor that we love.

Extruders have been completely revolutionizing the production process is becoming increasingly easier, inevitable, the same as ramen noodle machine made by Jinan MT. Booming of Snacks: Preparing snacks like chips Popcorn was freaking important because they take a lot more time and hard work. It was not easy at all. With extruders however, more and faster snacks can be made. Which means more chocolate for us.

Food Extruder system will work perfectly and Can prepare identically tasting snacks every times, similar to the Jinan MT's product like oats flakes making machine. It is composed of various elements that create top-notch food. The screw restrict is one central a part of the extruder. The screw mixes the ingredients and cooks them. This mechanically sends the ingredients out of a small opening on one side or end of the extruder where it has been transformed into another form that we can consume.

New applications of extrusion to produce health snack products For example, snacks made withextruderscan add vitamins and minerals to us for the purpose of health, as well as the soybean extruder for sale supplied by Jinan MT. The easiest way to do so, too we can meet our nutritional needs while eating foods that love mine. Moreover, there are more exotic sources of protein used in extruded snacks like insects or algae that can be potentially good for not only our health but the planet too

Extrusion can also be used to develop eco-friendly food products, identical to Jinan MT's product noodle making machine commercial. Given that extruders may apply a broad variety of ingredients, they can also minimise food loss by processing those same foods into products when otherwise would have been wasted. Very important for reducing food waste. Extruders not only able to produce meat alternatives, but these solutions are also environmentally friendly compared with traditional meat products so customers who would like to eat in a sustainable way it is the perfect option.

Specialized in RD and Extruder in food industry extrusions, with over 15 years of of history and 20000m2 factory Our equipment earns us a good standing on the market. We provide a complete turnkey service from raw material process to packing system, which includes MCC control system. The entire line of processing is an extremely high degree of productivity and automation. It is possible to customize the process according to customers' request.

Extruder in food industry offers excellent after-sales assistance customers worldwide includes fast responses clear smooth communication technical support ensure any issue can quickly addressed experienced team is hand assist any issues questions providing quick efficient solutions approach support led an increase customer satisfaction strengthened status reliable partner international trade focusing needs customers maintaining open lines communication MT machinery ensures clients receive best level support care commitment providing exceptional after-sales services not improves customer purchasing experience also fosters long-term friendly cooperation relationships them

With more than 20 years of engineering experience, we have several unique patents related to food extrusion equipment and projects that include a multi-choice Extruder in food industry drying system, high-precision food extrusion systems and a unique corn flattening machine with a complete automated packing and stacking system etc.We can offer formulas for production Installation and debugging assistance along with operator training, until products are manufactured to your satisfaction.Our solution has superior quality and value, as well being high in efficiency and energy savings.

A Extruder in food industry supply chain, a huge production capacity, and a wide range of extrusion machines to make food are the main strengths. Flexible and able to offer personalized services. They have strict and independent standards and auditing procedures.