Introduction Of course pets need food just as we do, but how are their meals served. Pet food extruders: these are special machines that prepare pet foods as well. This is so dope because these puppies churn out all sorts of pet food for dogs, cats, birds and even fish. Read on for some intriguing facts about pet food extruders and what is involved in an individual process

Like massive Play Doh machines, pet food extruders take ingredients of real food and make things that look like kibble. This boils down to using various ingredients into something, which is placed through the machine and shot out in cool shapes for pets as treats. Begin by mixing the ingredients together, so all are well-incorporated. The Jinan MT puff extruder machine are then driven through a long tube. The tube requires a ton of pressure because the food is expell from this end. While the ingredient passes the tube, additionally this machine helps in cooking of food too. Both the pressure and heat from releases near simultaneously will cook all food down as it flows out, therefore safe to taste when heads exit thanks for a nice treat.

Due to their widespread use, pet food extruders have really revolutionized the way we produce pet food. Before these wonderful machines existed, pet food was made by combining the ingredients and then baking them in an oven. It was a time consuming process and could not do many types of food. Pet food extruders-the faster alternative In this way these machines allow you to make some types of food for a lot of pets. Admittedly, these days it is possible for our pets to have delicious meals that they will relish eating and made from wholesome stuff.

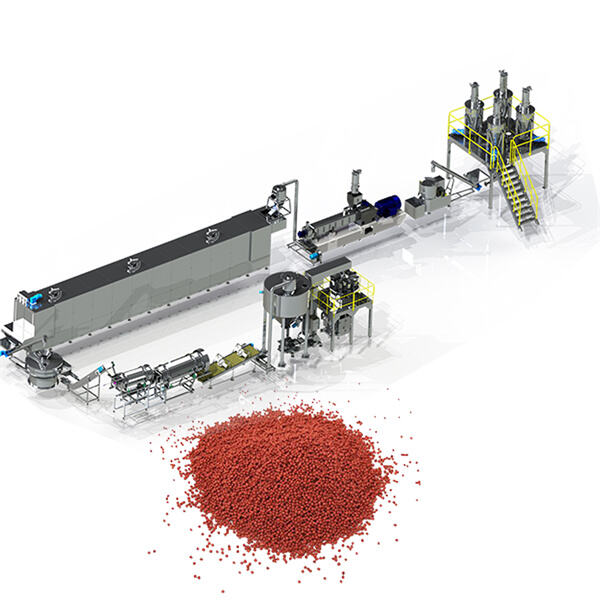

Pet food extruders are the type of Jinan MT pet food extrusion machine used in factories to make a large amount of pet food at once. Many factories use multiple extruders that work simultaneously to produce various pet-food flavors and forms. A great thing for pet owners as this means there are a range of food options out their when feeding your furry friends. The food is cut into small pieces as it exits the extruder which makes it easier for pets to eat. Afterward, the food is bagged or canned. After this, the processed food is shipped to pet shops where animal owners can buy it.

One of the things that you should know about pet food extruders is just how versatile these machines are. Food suitable for cats, dogs, birds, fish and even farm animals are made. The machines can produce foods of various sizes, shapes and textures. This aids pet food producers in making the perfect feed for different animals. As cat food needs to be much smaller and a different shape than dog food, pet food extruders are built in such a way that they can do this for you easily! That implies that any kind of pets in essence can eat this type of pet food.

Extruders for pet food are continually seeing improvements. Jinan MT pet food extruder machine manufacturers are constantly searching for novel strategies to develop even tastier but healthier pet foods. Over the years there has been numerous new design elements in pet food extruders but one of newest ideas is to blend probiotics or natural topic ingredient. Similar to what they do for humans, probiotics are good bacteria that help pets with digestion thus making those tummies feeling loads better. Pet food which is made of natural ingredients means there are not any added things more than pets need so it shows its better for health.

Our equipment has built a strong recognition in the marketplace. We provide a turnkey service, from raw material preparation to Pet food extruders, with MCC Control System. The entire process line is an extremely high degree of productivity and automation. The customization is based on the needs of the customer.

With more than 20 years experience of our Pet food extruders as an engineering team, we hold several unique patents related to food extrusion machinery and projects, such as multi-choice low energy drying system, high precision food extrusion system Unique corn flattening machine fully automated packing and stacking system etc.We offer production formulas installation, debugging, as well as operator training service until satisfied products can be manufactured.Our solution offers superior quality and value, as well with a high degree of efficiency and energy savings.

A strong supply chain, an enormous production capacity, and a Pet food extruders of extrusion machines for food are all strengths. Able to provide customized services and strong flexibility. Standards that are rigorous and independent and auditing procedures.

MT machinery provides excellent after-sales support international customers includes prompt responses clear Pet food extruders technical support making sure any problems quickly resolved team dedicated professionals ready help any concerns questions quick efficient solutions proactive approach service resulted substantial increase customer satisfaction consolidated reputation trustworthy partner international trade focusing needs clients maintaining open lines communication MT machinery ensures clients receive best levels care support commitment excellent after-sales support improves buying experience customers also promotes positive long-term relationships them