Dog food process ingredients such as meat, vegetables and grains form the basis for making dog food. These ingredients are the additional flavorings of Jinan MT dog food making machine that help this specific nutrition food taste great, and also keeps your dogs muscles strong and healthy. Secondly, the ingredients require a proper washing and prep. This is vital for the food to be considered safe in order that dogs are able to consume it. These cleaned up ingredients are kneaded to form a dough like mixture.

Although dog food is tasty, it isn´t just a snack — for man´s best friend too, his meal must contain all of the essential nutrients he needs to stay healthy. Jinan MT are the building blocks for dog food process; They help dogs grow, fix injuries and get bouncy so they can play. Much like we require vitamins and minerals, dogs need essential nutrients as well.

This is why there are dog foods with specific special body function and type of dogs in mind. For example, dog food processing plant are foods specially made for puppies who need more nutrients while they continue to grow. Similarly to cats, there are also foods in the range for older dogs who might have different requirements. There are also dog foods which can be eaten by dogs with allergies or sensitive stomachs. This is because dogs require typical nutrients in their diets based on breed d origin, size and especially age for better health.

Dog food process companies use quality control to ensure their food is safe and healthy by dog food processing equipment. To test them at different stages of production in Jinan MT, they apply multiple ways in which the food is tested. It helps them to test for any issues before the food is distributed out to stores so that dog owners can purchase it.

Finally, as Jinan MT continue to develop fondness for our four-legged friends, dog food companies have shortened up about their impact on the world around us through the use of dog food extruder machine. Several organizations are adopting options that reduce their ecological effect. For instance, dog food process may include renewable energy sources in their production processes, utilize waste material recycling and even adopt packaging reduction strategies.

Also, some of top performing dog food process companies like Jinan MT are making use natural ingredients to help the environment. It allows them to make selections perfect for the planet — they can pick ingredients that are farmed sustainably. They may, for example, employ organic ingredients that are not grown in pesticides in dog food manufacturing process. This is not only healthier for the dogs eating food, but also better for our planet.

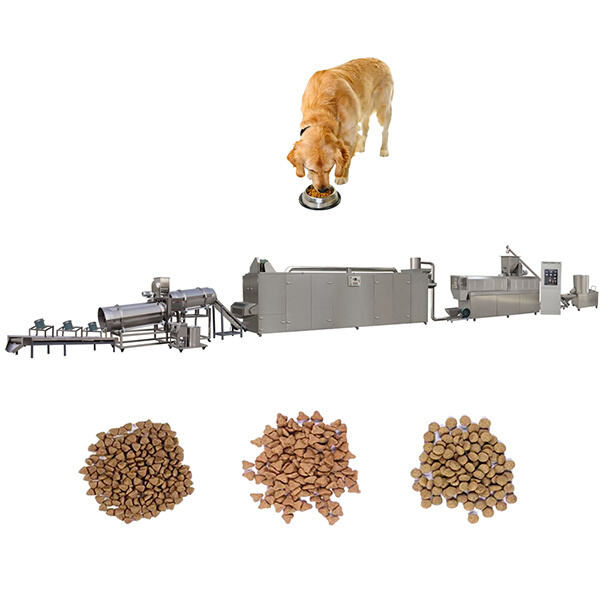

A strong supply chain, an enormous production capacity, and a Dog food process of extrusion machines for food are all strengths. Able to provide customized services and strong flexibility. Standards that are rigorous and independent and auditing procedures.

We have a 20-year engineering team and hold numerous patents for food extrusion and other projects, such as a multi-choice low-power drying system, patented high accuracy extrusion machine, patented corn Dog food process, patented full automatic packaging and stacking system.We offer production formula as well as installation and debugging services, as well as instruction for operators, up to the point that products are produced to your satisfaction.When compared to our competitors our product offers superior efficiency, energy saving superior quality with a competitive price as well as complete support before and after the sale.

Experts in RD and manufacturing of food extrusions with more than 15 years history and a 20000m2 facility Our machine has a great reputation on market. We provide a complete turnkey service starting with raw material processing to packing system using MCC control system. The entire Dog food process is an extremely high degree of automation and energy efficiency. It is possible to customize the process according to customer's requirements.

MT machinery provides excellent after-sales support international customers includes Dog food process inquiries clear concise communication technical assistance ensuring any issues can quickly addressed team dedicated professionals available assist questions issues offering quick effective solutions proactive approach customer service resulted substantial increase customer satisfaction increased standing reliable partner international trade MT machinery offers best possible service support customers focusing needs maintaining open lines communication commitment providing exceptional after-sales services only improves experience customers purchasing us also helps build long-lasting relationships cooperation them