Pet food ingredients can be sourced from a wide variety of places. Meats, grains (rice and corn), vegetables like carrots or peas sometimes plus fruits such as blueberries or apples these ingredients are used. These ingredients are scrutinised very closely before being used to ensure they can not do any harm or be unsafe for animals. That's an essential step to keep our puppies secure.

When all of the ingredients are assembled in the Jinan MT pet food processing machinery and checked, they're combined together, reduced and prepared. This part is difficult because every ingredient requires different cooking time and a temperature that make it perfect. For instance, meat may require considerably more cooking time than vegetables.

There are specific rules which Jinan MT pet food manufacturers must abide to, in the production of proper and personal healthy dog foods. For instance, pet food must contain some nutrients such as protein and vitamins; it also can not have any toxic substances so that dogs or cats do not get sick if they eat them. The pet food needs to be manufactured cleanly and in a way that contaminants or things like pathogens are not present.

A major challenge with producing pet food is trying to make it as palatable as possible, while keeping the product healthy. They like their food the way, we people do (mm yummy) but they also need to be healthy isn't it. Make sure it tastes good, but does not have too many calories if you are trying to stay within a calorie budget (which is the most effective way of losing fat), or at least all its nutrients more than compensates for that.

This challenge is a source of collaboration with pet food makers working together with nutrition experts who are well aware about what our pets should be fed. They assist in formulating diets that are tailored for dogs and cats. Pet food companies may also utilize unique ingredients and some sneaky methods in the dog food processing equipment to improve the taste of pet foods, but at the same time maintain this healthiness. Or else, pets will be able to consume their food with nutrients being fed on.

Packaging — the food is packaged into bags, cans or other vessels as soon as it cools. The packaging itself is also created so that the food remains protected and fresh until its opened up and consumed by your pets. The proper packaging helps in guarding against any external germs and also maintains the taste of food for our fur babies.

So as you can see a lot of work goes into the making of pet food. Good food for our dogsYou probably already know that the makers of dog and cat foods work hard to deliver nutritious diets formulated with so-called “complete and balanced” formulas, but they do much more than just choose a bagged kit off a shelf. The Jinan MT dog food processing machine want every meal to be both nutritious and tastes.

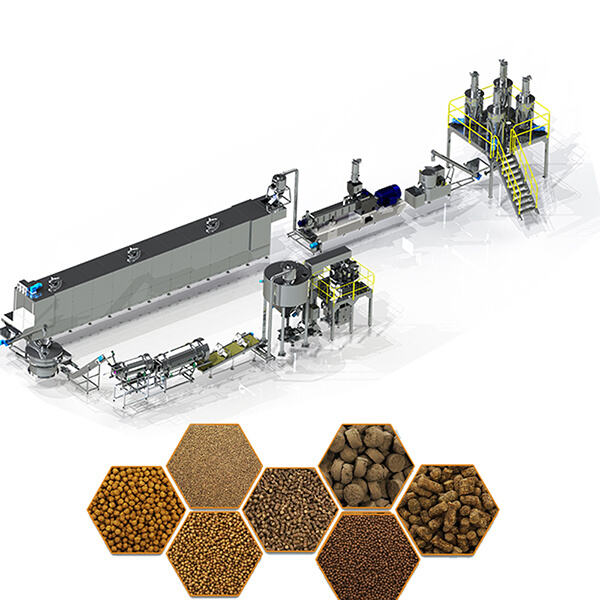

Our equipment has built a strong recognition in the marketplace. We provide a turnkey service, from raw material preparation to Pet food production process, with MCC Control System. The entire process line is an extremely high degree of productivity and automation. The customization is based on the needs of the customer.

MT machinery provides outstanding after-sales service international customers includes prompt response times clear efficient communication technical support ensuring any issues Pet food production process quickly team dedicated professionals assist you any query issue arise providing quick efficient solutions proactive approach customer support led increase satisfaction customers consolidated status reliable partner international commerce focusing needs clients maintaining open line communication MT machinery ensures our clients receive best quality service support commitment excellent after-sales support only improves experience buying customer also promotes positive long-term cooperation them

We have a 20-year team of engineers and hold Pet food production process for food extrusion equipment and projects. These include a multi-choice low power consumption drying system and patented high-precision extrusion technology, patent-pending corn flattening equipment, patented full automatic packaging and stacking system.We offer production formula, installation and debugging service, as well as instruction for operators, up to the point that products are produced to your satisfaction.Our solution has superior quality and pricing, as as high levels of energy efficiency and savings.

Strong supply chain and production capacity as well as a variety of Pet food production process. Flexible and able to provide custom-designed services. Standards that are rigorous and independent and auditing procedures.