Did you ever wonder what all those ingredients in a can of pet food were for anyway? The meat, grains and fats vegetables have all natural ingredients with vitamins included. The above ingredients are assembled first, as pet food is to be cooked. They are really selected nicely, leading to a fresh and clean force supply for manufacturers. The Jinan MT pet food processing machine reason for this is we only want the best quality of food that we hand over to our pets

When all those ingredients get to the plant, it is time to make pet food. Machines that mix the ingredients together are called Mixers. The machine is design purposefully to mix all these ingredients in right combination so on the every bite of pet meal can avail you proper nutrition. This ensures that all of the ingredients are thoroughly mixed together to make sure our furry friends have exactly what they need, when it comes time for a meal.

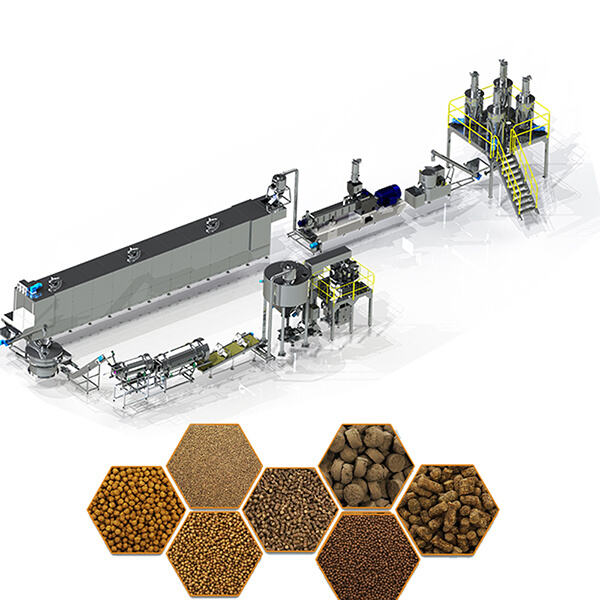

Once mixing is complete, it is extruded. The mixture is heated up and put through a machine in an extrusion process. This process helps to cook the ingredients and also mold that pet food into those familiar kibbles or shapes we find in bags. Kind of like the dough that is rolled into balls when forming cookie shapes

Food Factories for Pets Safety and Quality First They want to put care into what your pet consumes. The pet food goes through a whole battery of tests before it is packed into bags. For screening various dangerous things like bacteria or mold, these tests are done. If issues emerge, a batch of pet food is discarded to ensure the safety for the pets.

They have to follow same strict safety rules as the factory. Back In Business — Workers with special clothes and following cleanliness rules to prevent pet food from being contaminated. As a result, it ensures the Jinan MT pet food production plant is kept in good condition while also guaranteeing that your pet does not suffer from any dangerous products.

Pet food factories are perpetually searching for new and innovative methods to improve the quality of their products. In doing so, they adapt new techs and thoughts to give furry paw holders an even better food alternative for their pets. The other exciting new technology is sensors. These sensors, that can even check the pet food while it's being produced. They monitor changes, and if necessary can tweak things to make sure the food remains A-1.

Innovation is also key for developing novel Jinan MT dog food processing plant. Insects have been utilized in pet food, by some companies. Insects are a disease-ridden and overused source of protein that could be great for our pets, but even better for the planet.

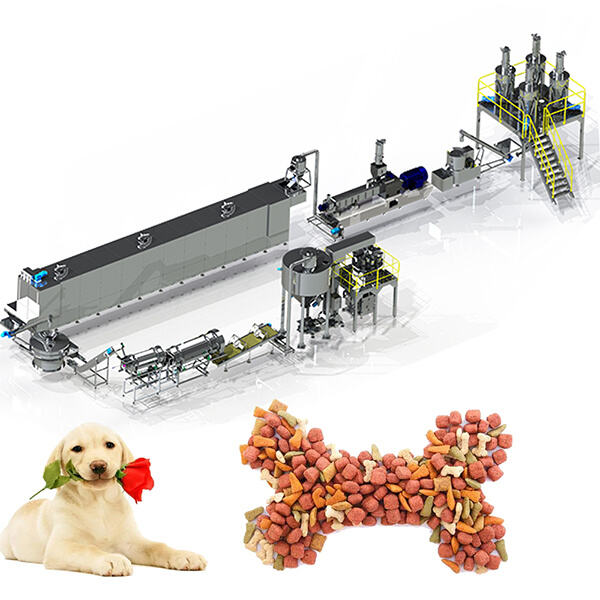

Our equipment has built a strong recognition in the marketplace. We provide a turnkey service, from raw material preparation to Pet food processing plant, with MCC Control System. The entire process line is an extremely high degree of productivity and automation. The customization is based on the needs of the customer.

MT machines provide excellent after-sales services to its international customers this includes prompt responses clear and seamless communication as well as technical support making sure that any problems can be solved quickly our experienced team is willing to assist you with any inquiries or problems with quick and effective solutions this proactive service approach has resulted in a substantial improvement in satisfaction of our customers and has helped us establish our status as a trustworthy partner for international trade by Pet food processing plant on the demands of our customers and maintaining open lines of communication MT machinery ensures that our customers receive the highest levels of care and support this dedication to superior after-sales service not only improves the purchasing experience for our customers and creates a friendly long-term relationships with them

We have a 20-year engineering team and hold numerous patents for food extrusion and other projects, such as a multi-choice low-power drying system, patented high accuracy extrusion machine, patented corn Pet food processing plant, patented full automatic packaging and stacking system.We offer production formula as well as installation and debugging services, as well as instruction for operators, up to the point that products are produced to your satisfaction.When compared to our competitors our product offers superior efficiency, energy saving superior quality with a competitive price as well as complete support before and after the sale.

A Pet food processing plant supply chain, a huge production capacity, and a wide range of extrusion machines to make food are the main strengths. Flexible and able to offer personalized services. They have strict and independent standards and auditing procedures.