Making cereal by hand a hundred years back. This meant making cereal took forever: it could take hours, and in some cases even days. All these had to be done by manual labour, and this brought the progress on boiling point (what is it with farmers boycotting?) This allowed consumers to make a quick breakfast with warm cereal suitable for home and on the go when it was invented in 1906. Using this amazing equipment developed over decades, today farmers are able to grow cereal in huge quantities and process it much faster making the production of cereals more efficient than before which was not possible with simple tools.

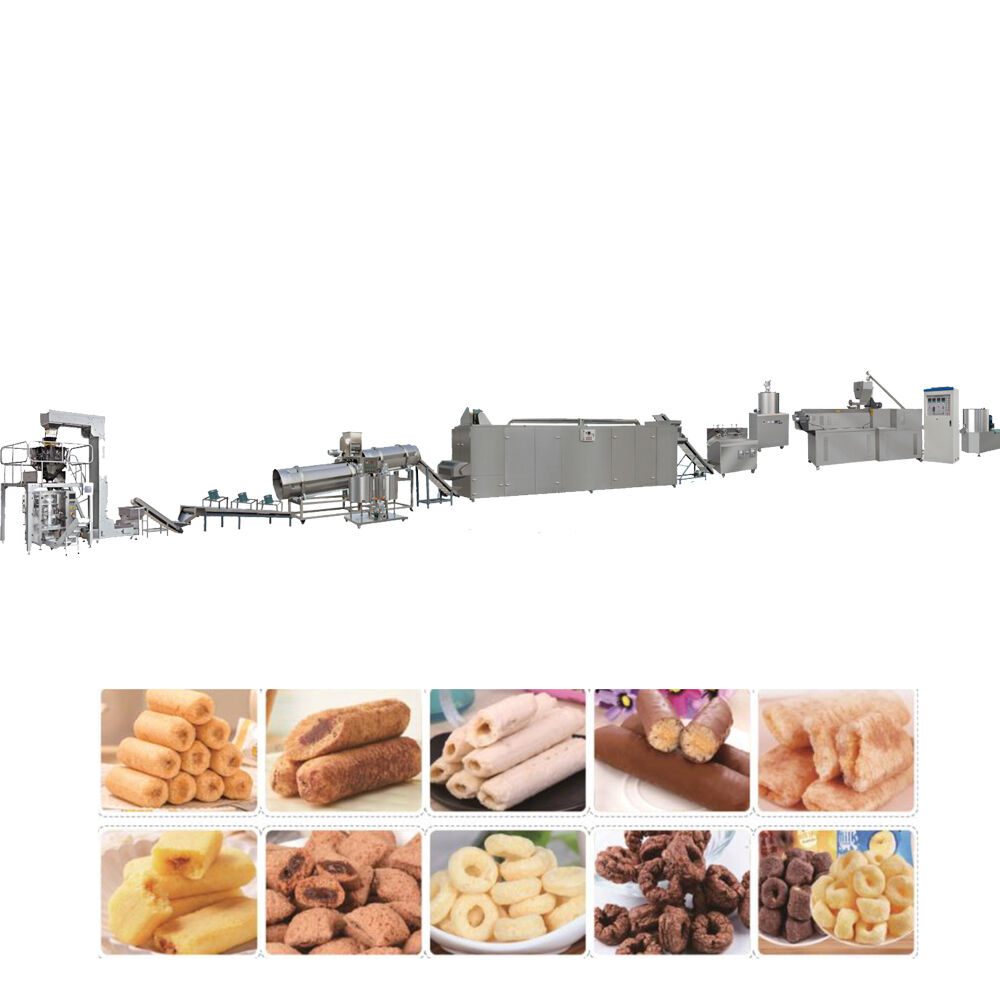

There are many different devices that a part of cereal processing equipment, which all work with each other to manufacture the processed grain. For example, there are Jinan MT breakfast cereal machine that process to clean them and sort so only the good grains can be used. Every mill is different, and some have equipment that makes the cereal as we know it from grain for example there are machines to turn grains into flour and then other machines where they will make the cornflakes or whatever you eat. If not, these machines all work together to ensure our cereal is perfect for you every morning (all part of a complete breakfast).

But the main work of cereal processing equipment goes well beyond speeding up how fast we can make a bowl of cornflakes. It also contributes to making cereals more suitable for our meals. Cereals contain a high amount of nutrients such as fiber, vitamins and minerals that our bodies benefit from. This is not great; unfortunately, the process of making cereal can deprive it of these essential nutrients but sometimes.

Fortunately, Jinan MT cereal processing equipment is set up such a way to retain the health benefits of cereals; and in certain cases even better. For instance, some machines might do a brand new job of taking off the outer layer where most with the fiber is identified. This means that the end product is still a fiber-rich cereal, very important for digestion. And also, the machine can inject these vitamins and minerals back into the cereal for us to live a healthy lifestyle including eating cereals every morning.

Brand new cereal machines are made to waste less and use less energy. This means that less water is used when processing cereal, which lowers waste and helps to save infrastructures. Furthermore, Some Jinan MT breakfast cereal making machine are produced as energy-efficient that gives out similar quantity of cereal but consumes less power. It is a win-win solution to systemic food security and environmental challenges.

The cereal processing equipment is highly advanced on its own that it can just perform many tasks by itself. Which makes the machines such that they can work for a while before humans must assist them again. With automation being used for this, time and manpower will be saved. Regardless, this new learning equipment and to oversee how making cereal is being one can never know if all works are going right or not

Cereal processes machinery can be modified to produce variations of cereal. Some machines are only made for producing rice cereal but not wheat cereals. That is to say, there while the fact that want what kind of cereal people have a device which can produce any type. This cereal puffing machine is also flexible in that it can make higher or lower throughput of cereal as the demand fluctuates. This is essential in terms of consumer demand since it means that cereal processing equipment can fulfill whatever needs to be done, whether a small amount or large.

Specialized in RD, manufacturing of food extrusions, with over Cereal processing equipment of of experience and 20000m2 of factory space Our machine has a great reputation on market. We offer a turnkey solution from raw material to packing system using MCC control system. The whole processing line has high automation efficiency, energy efficient and high efficiency. Customer's requests are accommodated.

Cereal processing equipment have a 20-year team of engineers and hold numerous patents for food extrusion equipment and projects. These include a multi-choice low-power drying system, patented high accuracy extrusion technology, patent-pending corn flattening machine, patented fully automated stacking and packaging system.We offer production formula installation and debugging, as well as instructor training, up until our products are made to your satisfaction.Our solution offers superior quality and cost, as well as a high level of efficiency and energy savings.

MT machines provide excellent after-sales services to its international customers this includes prompt responses clear and seamless communication as well as technical support making sure that any problems can be solved quickly our experienced team is willing to assist you with any inquiries or problems with quick and effective solutions this proactive service approach has resulted in a substantial improvement in satisfaction of our customers and has helped us establish our status as a trustworthy partner for international trade by Cereal processing equipment on the demands of our customers and maintaining open lines of communication MT machinery ensures that our customers receive the highest levels of care and support this dedication to superior after-sales service not only improves the purchasing experience for our customers and creates a friendly long-term relationships with them

A strong supply chain, large capacity of production, and a selection of extrusion equipment for food are all strengths. Can provide Cereal processing equipment solutions and a lot of flexibility. Strict and reliable standards, as well as Audit mechanisms.